Introduction

CNC machining is a mechanical machining method based on computer numerical control technology. It realizes the machining operation of workpieces by programming and controlling machine tools. Compared with the traditional mechanical spindle machining method, the CNC spindle has many advantages, making it widely used in modern manufacturing. This article will detail the benefits of using CNC electro spindle machining.

High Efficiency

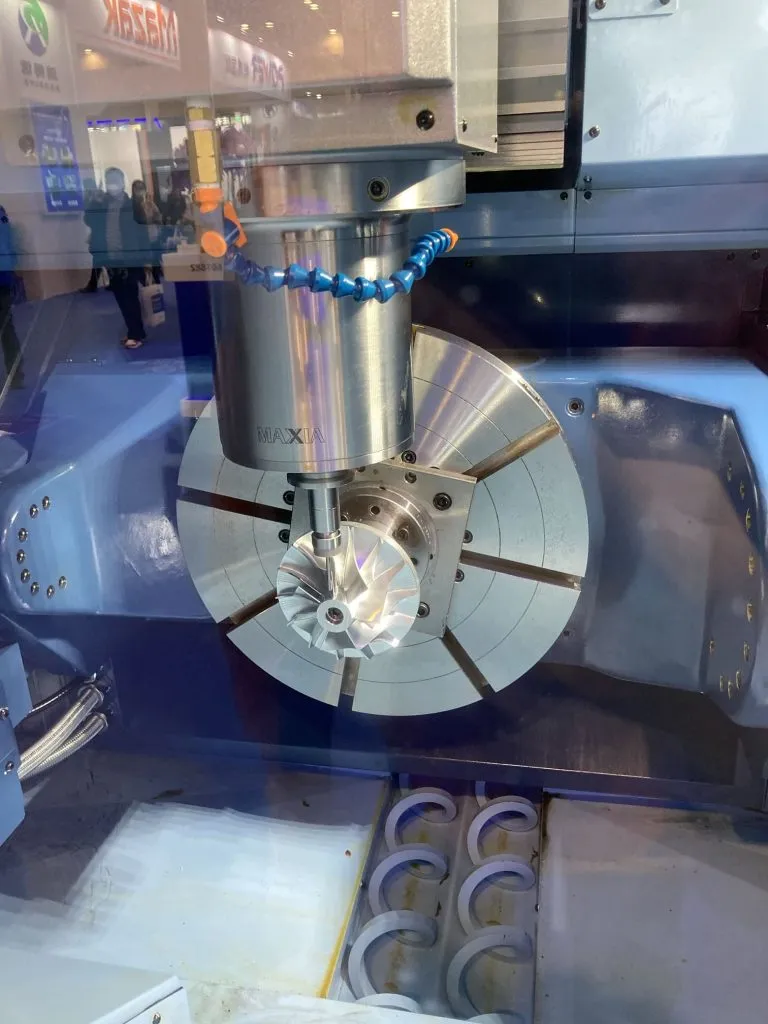

CNC electro spindle machining can realize automatic operation, reducing manual operation links and thus improving production efficiency. At the same time, since the CNC machining center can complete multiple machining tasks simultaneously, it can also reduce the clamping and replacement time of the workpiece, further improving production efficiency. In addition, the CNC spindle can also realize multi-axis linkage and efficiently machining complex surfaces and shapes, thereby enhancing production efficiency and machining quality.

High Precision

The precision of CNC spindle machining is very high. It can achieve micron-level machining accuracy, ensuring the quality and stability of the workpiece. Since CNC machining is digital control machining, it is almost unaffected by human factors, so the probability of errors is extremely low. Moreover, the CNC spindle can adjust parameters through programming control to ensure machining quality and precision.

Full Automation

The use of CNC electro spindles enables highly automated operations, reducing manual operation steps and thereby reducing the labor intensity of workers. Additionally, since CNC processing is digital control processing, it can achieve 24-hour uninterrupted processing operations, thus improving production efficiency and reducing production costs. CNC processing can also realize automatic detection and identification of workpieces through automated detection technology, ensuring the quality and stability of workpieces.

Programmability

The electro spindle allows for control of machine tools through computer programming, making it possible to perform different processing operations. This flexibility and adaptability make CNC processing suitable for various market needs and types of workpieces. Furthermore, since CNC spindle processing involves digital control, computer simulation technology can simulate the processing process and program correctness, ensuring processing quality and precision.

High Reliability

The reliability of CNC processing is very high, enabling long-term and stable processing operations. As CNC processing is digital control, human factors do not affect it, thus minimizing the risk of failures. Additionally, CNC machining can monitor and maintain machine tools through automated detection technology, ensuring the stability and reliability of the machinery.

Conclusion

In short, using CNC spindle machining offers advantages such as high efficiency, high precision, high automation, programmability, and high reliability. These benefits make it widely used in modern manufacturing. With the continuous advancement of science and technology and evolving market demands, CNC spindles will play an increasingly important role in the future manufacturing industry.

Summary FAQ Based on the Article

Q: What is a CNC spindle?

A: CNC spindle is a component of a CNC machine that rotates the cutting tool to perform precise machining operations on workpieces. It is controlled through computer numerical control technology, offering high efficiency and accuracy.

Q: What are the benefits of using a CNC spindle motor?

A: CNC spindle motor provides high efficiency, precision, automation, programmability, and reliability in machining operations. It reduces manual labor, allows for complex and precise machining, and ensures consistent performance.

Q: How does a CNC spindle enhance manufacturing processes?

A: CNC spindle enhances manufacturing processes by improving production efficiency through automatic and multi-axis operations, achieving micron-level precision, enabling continuous operation, and providing flexibility through programmability.

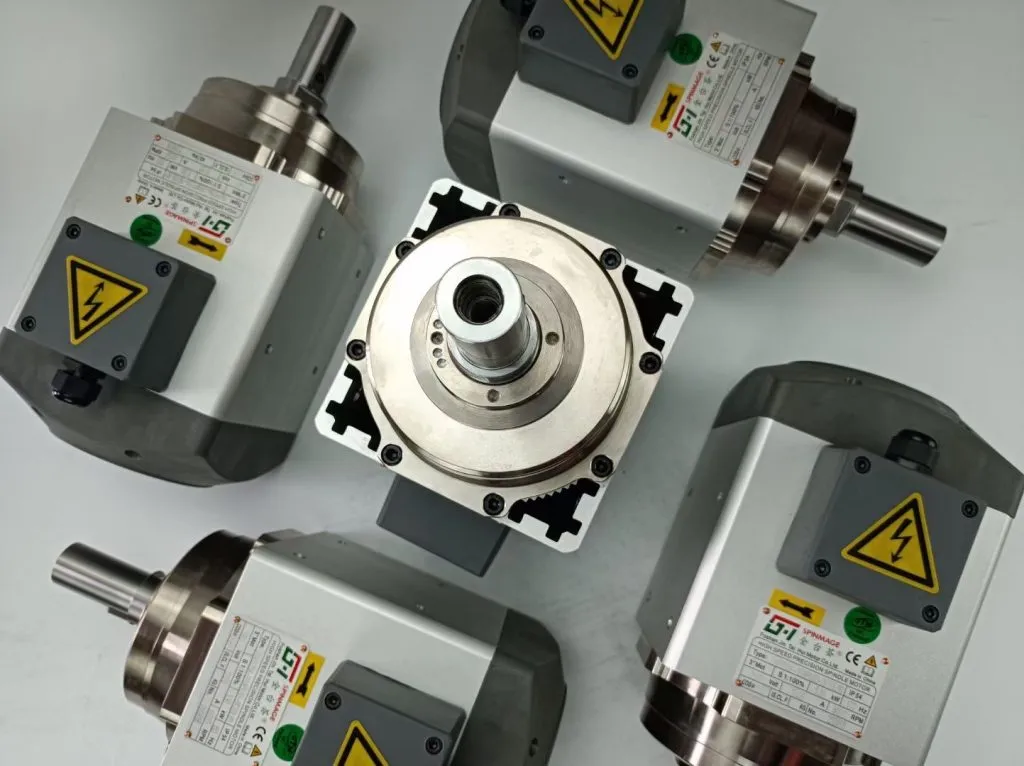

- RicoCNC has a team of professionals who have been engaged in the design, production, sales, and maintenance of electro spindles for many years. Our company accepts the purchase of various types of CNC spindles.

water-cooled CNC spindle motors

Edge banding machine spindle motors.

- If you need any CNC spindle, please contact us.