Introduction

In modern machining, the electric spindle is a key component for achieving high-precision machining and efficient production. Understanding the structure of the electric spindle, the functions and requirements of the spindle motor, bearing configuration, lubrication system and cooling system is essential to ensure the efficient operation of the electric spindle. So what is the structure of the electric spindle?

The structural form of the CNC spindle

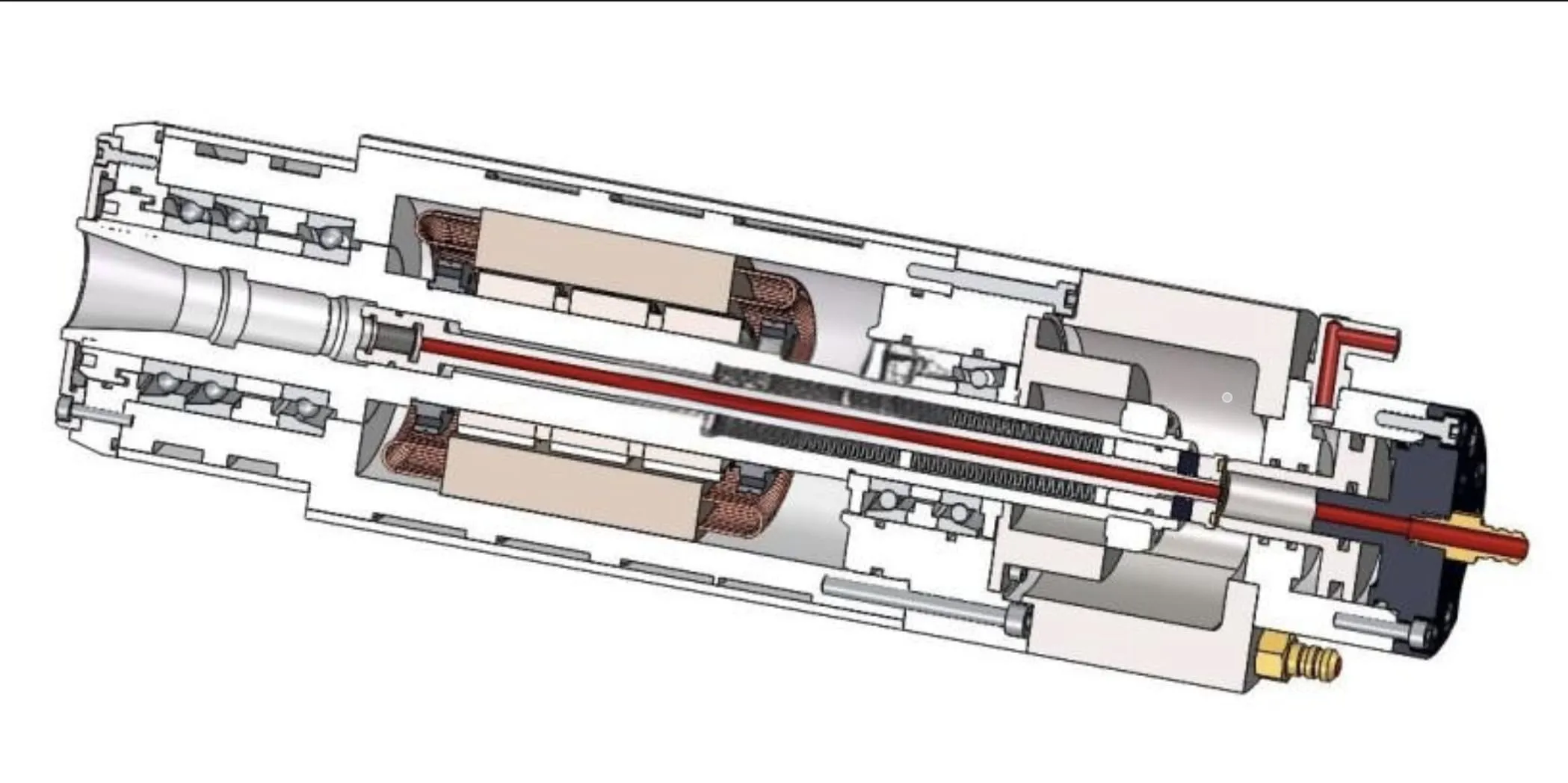

Two main structural forms of the CNC router spindle:

-

The motor is installed between the front and rear bearings of the spindle

This structural form of the electro spindle has two front and rear supports. Due to the relatively small axial size, the overall rigidity of the spindle is better, and the power is more significant. This design is particularly suitable for high-speed CNC machine tools and can provide excellent stability and rigidity.

-

The motor is installed behind the rear bearing of the spindle.

In this design, the motor and the spindle box are arranged in the axial direction of the spindle. This structure can effectively shorten the radial size of the front end of the spindle, which is beneficial to the heat dissipation of the motor. Still, the axial length of the spindle is relatively large. Therefore, this structural form is often used in small high-speed CNC machine tools.

Spindle motor

The spindle motor is an essential component of the electric spindle, and its technical parameters directly determine the performance of the electric spindle. At present, there are two common types of electric spindle motors:

AC synchronous motor

AC synchronous motors have a smaller volume, shorter startup time, higher power and torque at the same torque, and lower rotor power loss, which can effectively improve the thermal performance of electric spindles. Therefore, they are suitable for high-speed electric spindles.

AC asynchronous motor

AC asynchronous motors are moderately priced, have high limit speeds, are easy to maintain, and have simple control systems. Although their performance could be better than that of synchronous motors, they still have advantages in some applications.

Spindle bearings

Spindle bearings are one of the core components of electric spindles, which directly affect the high speed and high precision of electric spindles. The following points should be noted when selecting bearings:

Ceramic ball bearings

Ceramic ball bearings are made of high-temperature resistant, low-density ceramic materials, which can significantly increase the limit speed while having a smaller temperature rise and greater stiffness. Angular contact ceramic ball bearings are often selected to support electric spindles due to their high-speed performance and strong load-bearing capacity.

Magnetic bearings

Magnetic bearings achieve no mechanical contact through intelligent control, can reach twice the speed of rolling bearings, and are suitable for ultra-high-speed, high-power machine tools. However, due to the high manufacturing cost and heating problems, the application range is narrow.

Electric spindle lubrication

The lubrication of the electric spindle mainly forms a lubricating oil film on the friction surface of the bearing through the lubricant, reduces wear and friction, and ensures good operation. Lubrication also helps to dissipate heat and maintain the average working temperature of the bearing. Proper lubrication can extend the service life of the bearing and improve the operating efficiency of the electric spindle.

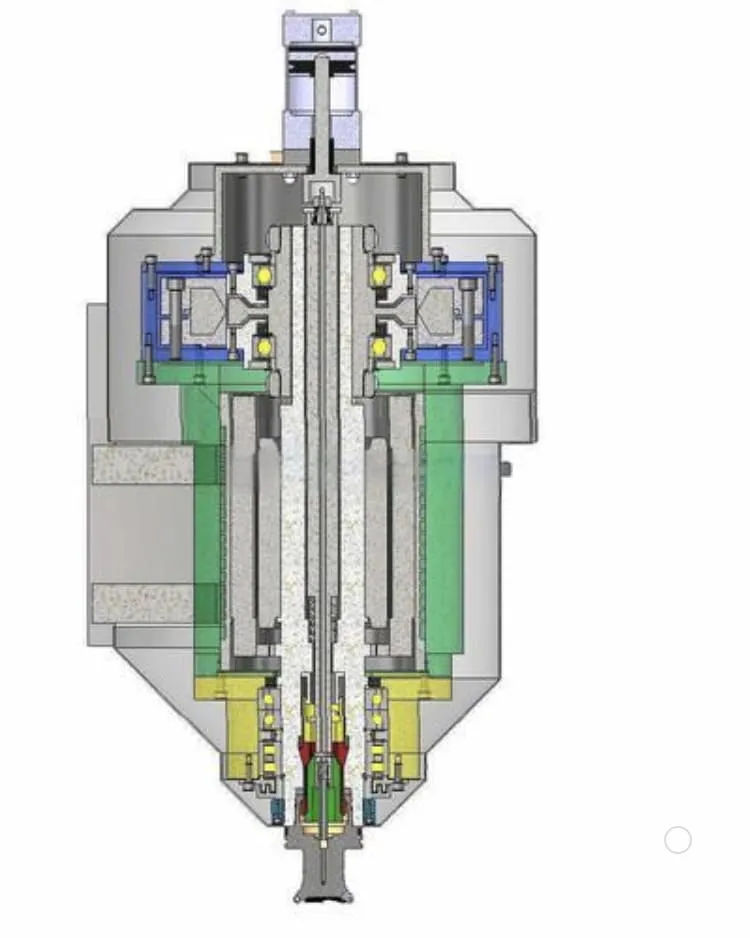

Electric spindle cooling system

The electric spindle will generate a lot of heat during high-speed operation, so it is necessary to design an effective cooling system. The primary cooling measures include:

Cooling device

The cooling device is installed on the outer wall of the electric spindle, which can keep the electric spindle at a low temperature during operation by circulating coolant to avoid damage caused by excessive temperature.

Encoder

The encoder is used to accurately control the electric spindle, realize automatic tool change, control the start and stop state of the ATC spindle, tap, threading and other functions.

Automatic tool changer

Installing an automatic tool changer on the electric spindle can improve the working efficiency of the machining center.

Tool selection method

For high-speed machining needs, high-speed tools that meet the machining conditions should be used instead of traditional tools to meet the requirements of high speed.

High-frequency frequency conversion device

In order to achieve the high speed of the electric spindle of tens of thousands or even hundreds of thousands of revolutions per minute, a high-frequency frequency conversion device is required, and the output frequency of the frequency converter must reach thousands or several thousand hertz.

Conclusion

Understanding the structural form of the electric spindle, the functions and requirements of the spindle motor, bearing configuration, lubrication system and cooling system is crucial to optimizing the performance of the electric spindle. Each component plays an important role in the overall operation of the electric spindle. Through reasonable selection and configuration, the stability, efficiency and service life of the electric spindle can be improved.

Summary FAQ Based on the Article

Q1: What are the two main structural forms of electric spindles?

A1: The main structural forms of electric spindles include the motor installed between the front and rear bearings of the spindle, which is suitable for high-speed CNC machine tools, and the motor installed behind the rear bearing of the spindle, which is suitable for small high-speed CNC machine tools.

Q2: What are the main differences between synchronous motors and asynchronous motors?

A2: Synchronous motors are small in size, have a short start-up time, high power and torque, and low rotor power loss, making them suitable for high-speed electric spindles; while asynchronous motors are moderately priced, have a high limit speed, and are easy to maintain, making them suitable for some applications.

Q3: What are the common types of bearings for electric spindles?

A3: Common types of electric spindle bearings include ceramic ball bearings and magnetic suspension bearings. Ceramic ball bearings are suitable for high-speed applications, while magnetic bearings are suitable for ultra-high-speed and high-power machine tools.

Q4: What is the main purpose of electric spindle lubrication?

A4: The main purpose of electric spindle lubrication is to reduce bearing wear and friction, ensure its good operation, and have a heat dissipation effect.

Q5: What are the main measures of the cooling system of the electric spindle?

A5: The cooling system of the electric spindle mainly includes a cooling device, a built-in pulse encoder, an automatic tool changer, a suitable tool clamping method, and a high-frequency frequency conversion device.

- RicoCNC has a team of professionals who have been engaged in the design, production, sales, and maintenance of electro spindles for many years. Our company accepts the purchase of various types of CNC spindles.

water-cooled CNC spindle motors

air-cooled CNC spindle motors

Edge banding machine spindle motors.

- If you need any CNC spindle, please contact us.