In the world of CNC machining, files are the bridge between your ideas and tangible creations. If you have ever wondered, “What is a CNC file?”, this comprehensive guide will break down everything you need to know—from file types to how these files are created and utilized in CNC manufacturing. We’ll cover how CAD, CAM, and G-code files all contribute to the efficient and precise functioning of CNC machines.

Understanding CNC Files

What is a CNC File?

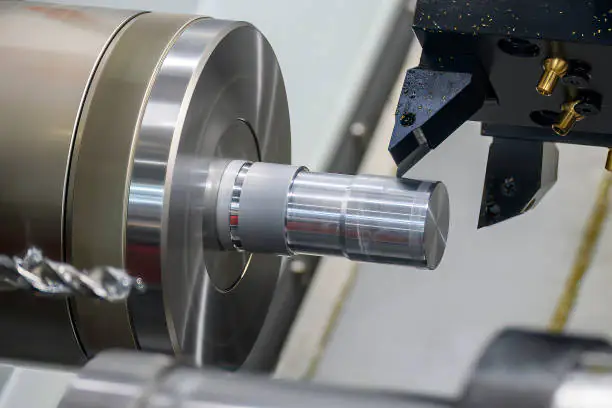

A CNC file is a digital document that contains the instructions for a CNC (Computer Numerical Control) machine to perform specific operations like cutting, milling, or drilling. These files direct the machine on how to move, how fast, what paths to take, and when to change tools, among other details. CNC files are essentially the blueprint for automated manufacturing.

These files come in various formats, and they play different roles throughout the CNC process—from design creation to toolpath generation and execution on the machine. The process starts with a CAD file and ends with G-code, which directly controls the CNC machine.

Types of CNC Files

CNC files fall into several categories, each serving a unique purpose in the machining process:

- CAD Files (Computer-Aided Design): These files represent the design and geometry of a part. Common file types include .DXF, .DWG, and .STL. CAD files are created in design software like AutoCAD or SolidWorks.

- CAM Files (Computer-Aided Manufacturing): CAM software takes CAD files and generates the necessary toolpaths. Common CAM files include .NC or .TAP, and these files help create the G-code used by CNC machines.

- G-code Files: The most important CNC file type, G-code files have the instructions that tell the CNC machine how to operate, move, and cut. G-code files usually end with extensions like .NC or .GCODE.

Internal Link: Explore our CNC Spindle Motors that can help you achieve more efficient CNC operations with precision and power.

The Process of Creating a CNC File

Step 1: CAD Design

The first step in creating a CNC file involves using CAD software. CAD stands for Computer-Aided Design, and it allows users to create a digital model of the part they want to produce. AutoCAD, SolidWorks, and Fusion 360 are some of the popular CAD tools used for designing CNC projects.

- Designing in 2D or 3D: Depending on the complexity of the part, you can create 2D drawings or full 3D models. For simple cutouts, a DXF file format suffices, while for more complex geometries, you may need a STL or STEP file.

- Saving the File: Once the design is complete, it’s saved in a format that can be read by CAM software.

Step 2: Converting CAD to CAM

The next step involves using CAM (Computer-Aided Manufacturing) software to translate the CAD model into machine commands. CAM software, such as Mastercam or Fusion 360, takes the CAD file and generates toolpaths that the CNC machine will follow.

- Generating Toolpaths: Toolpaths are the routes that the cutting tool takes across the material. These paths are generated based on cutting speed, depth of cut, and tool type.

- Creating G-code: After defining the toolpaths, the CAM software converts them into G-code. The G-code file is essentially the “language” of CNC machines.

Internal Link: To optimize your CNC process, consider using our 24000RPM 800W ER11 Water-Cooled Spindle for precision in every step.

Step 3: Running the CNC Machine with G-code

The final step is to load the G-code into the CNC machine. This is often done through a USB drive, an SD card, or directly from a computer connected to the CNC controller.

- Loading the File: Use the CNC machine’s control panel to navigate to the correct G-code file and select it for machining.

- Simulation: Some machines allow you to simulate the process first to ensure that there are no errors, such as collisions or incorrect toolpaths.

- Executing the Program: Once the setup is confirmed, execute the G-code to begin the machining process.

Common CNC File Formats and Their Uses

| File Format | Description | Use |

|---|---|---|

| .DXF | Drawing Exchange Format | 2D drawings for parts |

| .STL | Stereolithography | 3D models |

| .STEP | Standard for the Exchange of Product Data | Complex assemblies |

| .NC | Numerical Control | Toolpaths for CNC machines |

| .GCODE | G-code Instructions | Direct machine control |

CAD File Formats

- DXF: A widely used file format in CNC for 2D sketches, especially for cutting or engraving tasks.

- STL: Commonly used for 3D printing and CNC routing, STL files define the surface geometry of a 3D object.

- STEP: An open-source CAD file format used for sharing between different CAD software platforms. Ideal for complex parts.

G-code File Format

G-code files, such as .NC or .GCODE, are the final product of the CAD/CAM process. They contain the step-by-step instructions needed for a CNC machine to execute a project. Every movement, speed, and tool change is encoded in the G-code.

Internal Link: Learn more about how our 60000RPM 1.2KW ER11 Water-Cooled Spindle can enhance your CNC operations.

How CNC Files Enhance the Manufacturing Process

1. Precision and Accuracy

CNC files bring a level of precision that is difficult to achieve manually. By providing exact coordinates for every move, CNC machines can create highly complex parts with minimal human intervention.

- Consistency: Since CNC files ensure that the same instructions are followed every time, they help in producing consistent parts, ideal for large-scale production.

2. Reducing Material Waste

The precision of CNC machining and the accuracy of CNC files contribute to reducing material waste. Well-prepared files ensure that the toolpaths are optimized, avoiding unnecessary cuts and preserving material.

- Efficient Cutting Paths: CAM software optimizes toolpaths to minimize the cutting time and material wastage.

3. Enhanced Productivity

With CNC files, a machine can run autonomously once the file is loaded, freeing up the operator to work on other tasks. This feature greatly enhances productivity, especially in a production environment.

Creating Effective G-code Files

Tips for Effective G-code Generation

- Use High-Quality CAM Software: Programs like Fusion 360 and Mastercam offer advanced options for creating efficient toolpaths, resulting in fewer errors during the machining process.

- Double-Check Toolpaths: Always simulate the toolpaths in the CAM software before generating the G-code to ensure that there are no collisions or errors.

- Set Optimal Feed Rates: Incorrect feed rates can lead to tool wear or poor-quality cuts. Make sure that the feed rate is appropriate for the material and tool being used.

Internal Link: Improve your CNC projects with our high-quality 1.5KW ER11 Round Air-Cooled Spindle.

FAQs

1. What are the most common CNC file formats?

The most common CNC file formats include DXF, STL, and STEP for design, as well as NC and GCODE for CNC machine operations.

2. How do I convert a CAD file to G-code?

You can convert a CAD file to G-code using CAM software like Fusion 360, which generates toolpaths and outputs G-code for CNC machines.

3. Can I edit G-code files manually?

Yes, G-code files can be edited manually. This is often done for minor adjustments, but a good understanding of G-code syntax is required.

4. What software do I need to create CNC files?

You will need CAD software to design parts, CAM software to create toolpaths, and a CNC controller to run the G-code on your CNC machine.

5. Why is G-code important for CNC machining?

G-code is crucial because it directly controls the CNC machine’s movements, speed, and tool actions, ensuring that the machine performs the operations correctly.

Conclusion

CNC files are an integral part of the CNC machining process, transforming digital designs into physical products with precision and consistency. From CAD design to CAM toolpath generation, and finally G-code execution, each type of CNC file plays a vital role in ensuring efficient and effective manufacturing. Understanding these files, their formats, and their roles in CNC operations is essential for anyone involved in CNC machining, whether at an amateur or professional level.

For all your spindle motor and CNC accessory needs, be sure to visit spindlemotorshop.com. We offer a wide range of products that can help you achieve top-notch results in all your CNC projects.