CNC (Computer Numerical Control) technology is revolutionizing the medical field, playing a pivotal role in the manufacturing of high-precision medical devices, implants, and surgical instruments. If you are wondering, “What is a CNC in the medical field?”, this article is here to provide you with a thorough understanding of how CNC machining is applied in medical technology, covering everything from production processes to material selection and quality control. Let’s dive into this innovative intersection between technology and healthcare.

Understanding CNC Machining in the Medical Industry

What is CNC Machining?

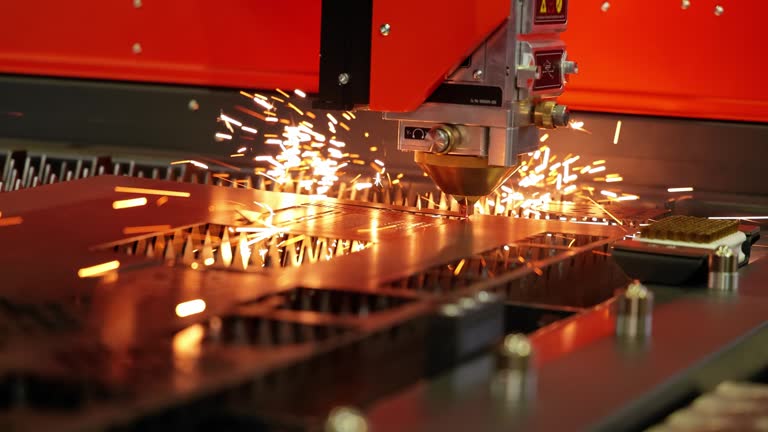

CNC machining is a technology-driven manufacturing process where machines use pre-programmed software to control the movement of tools. This technology allows for the cutting, drilling, and shaping of materials with high precision. In the medical field, CNC machining is responsible for producing implants, surgical tools, and medical device components with exceptional accuracy.

The importance of CNC technology in the medical field lies in its ability to manufacture complex parts that meet stringent safety and quality standards. In an industry where even slight deviations can have severe consequences, CNC machining provides the precision and reliability that medical manufacturing demands.

Why CNC Machining is Crucial in the Medical Field

CNC machining is crucial for the medical industry because it offers:

- Precision: High accuracy is critical when manufacturing medical implants that must fit perfectly into the human body.

- Customization: CNC machines allow for the customization of devices to fit specific patient requirements.

- Scalability: CNC technology makes it easy to scale production based on demand without compromising quality.

- Material Versatility: A wide range of materials, from metals like titanium to advanced polymers, can be used.

Types of Medical Devices Produced Using CNC Machining

1. Surgical Instruments

Surgical instruments such as scalpels, forceps, and bone saws are often produced using CNC machining. These tools must be made to exact specifications to ensure they perform reliably during critical surgeries.

- Material: Typically made from stainless steel or titanium to ensure durability and sterility.

- Process: CNC machines cut and shape these materials with exceptional precision.

2. Medical Implants

CNC technology plays a vital role in the production of medical implants, including hip joints, knee replacements, and dental implants. The parts must not only fit perfectly but also be biocompatible, meaning they do not cause adverse reactions in the human body.

- Materials Used: Titanium is commonly used due to its strength and biocompatibility.

- Customization: Implants can be customized for each patient, offering better integration and comfort.

3. Prosthetics and Orthotics

Another significant application of CNC machining in the medical field is in the production of prosthetic limbs and orthotic devices. CNC machines help in creating highly detailed and customized components, allowing patients to regain mobility and improve their quality of life.

- Precision Fit: The precise measurements enable a comfortable fit for individual patients.

- Material Flexibility: CNC can work with both metals and composite materials to create lightweight yet strong devices.

For high-quality and efficient machining, our 24000RPM 1.5KW ER16 Water-Cooled Spindle ensures precision, making it an excellent choice for medical CNC applications.

Materials Commonly Used in Medical CNC Machining

1. Titanium

Titanium is a popular material in the medical field because it is both lightweight and biocompatible. It is frequently used for making implants and prosthetics.

- Advantages: High strength-to-weight ratio, resistant to corrosion, and excellent biocompatibility.

- Applications: Hip replacements, dental implants, and bone plates.

2. Stainless Steel

Stainless steel is often used for surgical instruments and medical components. It provides the strength and durability required for repeated sterilization.

- Advantages: Strong, corrosion-resistant, and cost-effective.

- Applications: Scalpels, forceps, and surgical trays.

3. Polymers and Plastics

Polymers like PEEK (Polyether Ether Ketone) are used in applications that require lightweight and flexible materials.

- Advantages: Lightweight, resistant to chemicals, and capable of being sterilized.

- Applications: Catheters, lightweight braces, and certain types of implants.

CNC Machines Used in the Medical Field

1. CNC Milling Machines

CNC milling machines are widely used in the medical industry to create complex parts by removing material from a solid block.

- Precision: Milling machines can produce detailed and intricate parts with high accuracy, making them ideal for surgical instruments and implants.

- Speed: These machines allow for the rapid production of custom medical components.

2. CNC Turning Machines

CNC turning is used to produce cylindrical medical parts, such as bone screws and dental implants.

- Material Versatility: Suitable for materials like stainless steel and titanium.

- Customization: Turning machines can be used to produce parts that fit the specific requirements of patients.

3. Multi-Axis CNC Machines

For medical devices that require intricate geometries, multi-axis CNC machines are the go-to solution. These machines provide movement along multiple axes, allowing for more complex cuts and shapes.

- Complex Geometries: Suitable for implants and prosthetics that require high levels of customization.

- Efficiency: These machines can produce parts faster while maintaining accuracy.

Using a quality spindle like our 2.2KW ER20 Air-Cooled Spindle enhances the efficiency and accuracy required for producing complex medical components.

Applications of CNC Machining in Medical Devices

1. Production of Surgical Tools

CNC machining is commonly used for producing surgical tools due to its ability to create sharp, precise edges. These tools must meet rigorous safety standards and perform consistently in critical situations.

- Examples: Forceps, bone saws, and scalpels.

- Material: Surgical tools are typically made from stainless steel to withstand frequent sterilization.

2. Custom Implants

The ability to create custom implants is one of the significant advantages of CNC machining in the medical field. Each implant must be specifically designed to fit the patient perfectly.

- Precision Fit: CNC machining ensures that each implant matches the patient’s anatomy, reducing the risk of complications.

- Materials: Titanium and ceramic materials are used because of their biocompatibility.

3. Orthopedic Devices and Prosthetics

CNC machining helps manufacture orthopedic devices and prosthetics that provide support or replace missing body parts. These devices are often custom-made to ensure the best fit and function for the patient.

- Customization: CNC technology allows for unique adjustments based on patient measurements.

- Material Versatility: Devices can be produced using a mix of metals and lightweight plastics.

CNC Machining and Quality Control in Medical Manufacturing

Importance of Quality Control

In the medical field, quality control is of utmost importance. Any deviation in the production of medical devices can lead to serious consequences for patients. CNC machining helps maintain tight tolerances, ensuring each part meets stringent quality standards.

Standards and Certifications

Medical devices produced using CNC machining must comply with standards such as ISO 13485 and FDA regulations to ensure safety and efficacy.

- ISO 13485: Specifies the quality management system requirements for medical devices.

- FDA Compliance: Devices must be FDA-approved before they can be used in medical treatments.

Challenges in CNC Machining for the Medical Field

Material Challenges

The materials used in medical devices, such as titanium and stainless steel, can be challenging to machine due to their hardness. CNC machines must be equipped with appropriate cutting tools and spindles to ensure precision.

Tolerance Requirements

Medical devices require incredibly tight tolerances, often within micrometers. Maintaining such tight tolerances is challenging but essential to ensure the device performs as intended.

Surface Finish Requirements

The surface finish of medical parts is also critical, as rough surfaces can harbor bacteria or lead to irritation when implanted. CNC machining ensures that all parts have smooth, consistent finishes that are suitable for medical applications.

Advantages of CNC Machining Over Traditional Manufacturing

Precision and Accuracy

One of the most significant advantages of CNC machining over traditional manufacturing methods is its ability to produce parts with extreme precision. In the medical field, this precision translates to better patient outcomes and reduced recovery times.

Rapid Prototyping and Production

The use of CNC technology in the medical field allows for rapid prototyping. Engineers can quickly design, produce, and test medical components, allowing for faster innovation and development cycles.

- Prototyping: Medical professionals can test prototypes before they are mass-produced, reducing risks.

- Production: CNC machining makes it possible to ramp up production quickly to meet demand without compromising quality.

FAQs

1. What are the benefits of CNC machining in the medical field?

CNC machining provides high precision, customization, and scalability, making it ideal for producing medical devices, surgical instruments, and implants that require exact specifications.

2. Which materials are used in medical CNC machining?

Common materials include titanium, stainless steel, and polymers like PEEK. These materials are chosen for their biocompatibility and strength.

3. What types of medical devices are produced using CNC machining?

CNC machining is used to produce a variety of medical devices, including implants, surgical tools, prosthetics, and orthotic devices.

4. How does CNC machining ensure the quality of medical parts?

CNC machining ensures quality through precise control over production, maintaining tight tolerances, and using advanced quality control measures to meet ISO 13485 and FDA standards.

5. Can CNC machining be used for rapid prototyping in medical manufacturing?

Yes, CNC machining is highly effective for rapid prototyping, allowing for quick production and testing of medical device prototypes before moving to mass production.

Conclusion

CNC machining has become an indispensable tool in the medical field, offering unmatched precision, customization, and reliability. From surgical instruments to custom implants, CNC technology ensures that medical devices are produced to the highest quality standards, contributing to better patient outcomes. By understanding what CNC is in the medical field, we can appreciate the advanced level of technology that is helping to shape the future of healthcare.

To achieve the highest levels of precision and reliability in medical manufacturing, investing in quality CNC tools like our 2.2KW ER20 Air-Cooled Spindle is key. With the right equipment and expertise, CNC machining in the medical field will continue to make remarkable advancements in improving patient care and health outcomes.