Computer Numerical Control (CNC) machines have revolutionized the manufacturing industry by automating intricate processes and providing unmatched precision. CNC machines are now used to manufacture a wide variety of parts, from automobile components to delicate jewelry. This article will take a deep dive into what CNC machines do, how they work, and why they are so pivotal in today’s manufacturing environment.

Understanding CNC Machines

What Is a CNC Machine?

A CNC machine is a computer-controlled device used for the cutting, shaping, or machining of materials such as metal, wood, or plastic. Unlike conventional machines that are operated manually, CNC machines are controlled by computers using a specialized programming language called G-code and M-code. The goal is to automate all the key processes of manufacturing to improve accuracy, efficiency, and productivity.

CNC machines follow a precise set of commands, enabling them to:

- Carve intricate shapes into raw materials.

- Ensure repeatable accuracy across hundreds or thousands of units.

- Speed up production while minimizing waste.

How Do CNC Machines Work?

CNC machines operate through three primary components: software, hardware, and materials. Here’s a closer look at each component:

- Computer Software: Programming starts with CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software. These programs help machinists design the parts to be created and convert those designs into G-code that the machine can interpret.

- CNC Controller: The controller is the brain of the machine. It receives commands from the software and directs the machine on how to move and operate.

- Mechanical System: The machine’s mechanical components—such as the spindle, tool holder, and linear drives—execute the commands by moving along axes (typically X, Y, and Z).

CNC machines can also include features like automatic tool changers and coolant systems, adding to their efficiency and versatility.

Types of CNC Machines

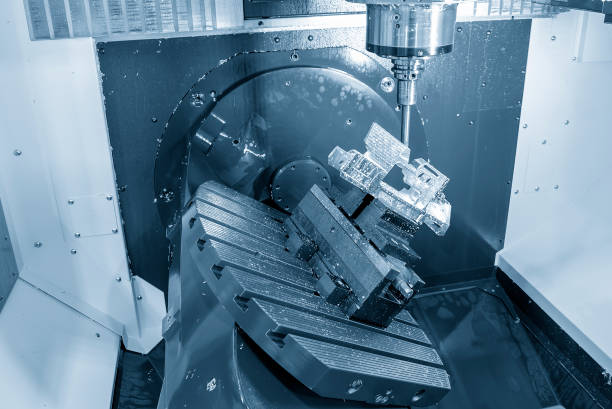

CNC Milling Machines

CNC milling machines are used to remove material from a workpiece using a rotating cutting tool. Milling machines are ideal for shaping metal or wood and are often used in:

- Automotive: For creating engine parts.

- Aerospace: For crafting lightweight but strong components.

| Features | Details |

|---|---|

| Number of Axes | Typically 3 to 5 axes |

| Common Materials | Metals, plastic, wood |

| Operation | Multi-axis rotation and cutting |

To learn more about spindles used in CNC milling, visit CNC Milling Spindle.

CNC Lathes

A CNC lathe is used primarily for creating cylindrical parts by rotating a workpiece against a cutting tool. This makes it ideal for producing shafts, pipes, and fasteners. CNC lathes operate using just two axes—X and Z.

Common Uses:

- Pipe fittings

- Engine parts

CNC Routers

CNC routers are similar to milling machines but are often used for lighter materials like wood, foam, and plastics. They are perfect for making signs, furniture, and custom parts. Unlike CNC mills, routers generally operate at higher speeds, which is ideal for softer materials.

CNC Plasma Cutters

Plasma CNC machines use a plasma torch to cut through materials like steel and aluminum. The plasma cutter operates by using a jet of hot plasma to melt the material, leaving a clean cut. This machine is suitable for sheet metal fabrication, HVAC systems, and other similar applications.

CNC Electrical Discharge Machines (EDM)

CNC EDMs work by creating an electric discharge between an electrode and the workpiece, effectively cutting through the material. This machine is useful for working with hard metals and creating intricate shapes that are difficult to achieve through traditional methods.

Applications of CNC Machines

CNC machines play a pivotal role across numerous industries, such as:

- Automotive: Manufacturing engines, gears, and transmission components.

- Aerospace: Producing lightweight and durable parts.

- Electronics: Creating complex PCB (Printed Circuit Boards).

- Medical: Crafting implants and surgical instruments.

Did You Know?

The precision of CNC machines allows aerospace manufacturers to craft parts that comply with strict safety regulations, such as those required by NASA or Boeing.

Benefits of CNC Machines

CNC machines offer several benefits that make them superior to manual manufacturing methods:

- Precision: CNC machines can produce parts with tight tolerances, often within a few microns.

- Repeatability: Once a design is programmed, a CNC machine can produce identical copies with no deviation.

- Increased Speed: By automating tasks, manufacturers can achieve production times that are impossible with manual machining.

| Advantage | Explanation |

|---|---|

| Automation | Reduces human error and improves accuracy |

| Efficiency | Allows continuous operation for 24/7 production |

| Complex Geometry | Capable of creating highly intricate parts |

CNC Software

CAD/CAM Software

CNC machines rely heavily on CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software. Popular software options include:

- AutoCAD: Widely used for 2D and 3D design.

- Fusion 360: A powerful tool for generating toolpaths and CNC programming. Fusion 360 is great for designing complex parts, especially when multiple axes are involved.

To learn how to use Fusion 360 for your projects, refer to this guide: How to Use Fusion 360 for CNC Router.

G-Code and M-Code

G-code and M-code are the languages used to control CNC machines:

- G-Code: Responsible for movement commands, such as positioning, cutting, and feeding.

- M-Code: Used for miscellaneous functions like turning the spindle on or off, changing tools, and controlling coolant flow.

For example, G01 is a code for linear movement, while M06 is used for tool change.

Materials Processed Using CNC

CNC machines are incredibly versatile and can process a wide range of materials:

Metals

- Steel: Widely used for automotive and industrial applications.

- Aluminum: Preferred in aerospace due to its lightweight and high strength.

- Titanium: Highly used in medical and aerospace due to its durability.

Non-Metals

- Wood: CNC routers excel in producing custom furniture.

- Plastics: Used for prototyping and lightweight components.

Composites

CNC machines can also handle composites like carbon fiber and fiberglass, which are popular in automotive and aerospace sectors.

| Material | Applications |

|---|---|

| Aluminum | Aerospace, automotive |

| Titanium | Medical implants, aerospace |

| Wood | Furniture, decorations |

| Carbon Fiber | Automotive, aerospace |

How to Get Started with CNC Machining

Step 1: Choose the Right CNC Machine

Selecting the right CNC machine depends on the type of work you want to do. Here are some factors to consider:

- Material Type: If you’re machining wood, a CNC router may be more appropriate, while metals require a CNC milling machine.

- Size and Scale: Consider the scale of production and the workpiece dimensions.

- Number of Axes: More axes provide greater versatility, but they also come with higher costs.

Step 2: Learn G-Code and M-Code Programming

G-Code and M-Code are the lifelines of CNC machining. Knowing the basics will allow you to tweak programs for more customized operations.

- G01 – Linear movement at a set speed.

- M08 – Turns coolant on.

- M30 – Ends the program and rewinds.

Step 3: Set Up and Test

Setting up involves attaching the tool to the spindle, configuring the workpiece on the bed, and calibrating the machine to ensure that the program runs smoothly. Before actual production, always conduct a test run to verify all measurements and parameters.

Conclusion

CNC machines are at the forefront of modern manufacturing, allowing industries to achieve high levels of precision, repeatability, and speed. Whether it’s the complex design of aerospace parts or the detailed craftsmanship of furniture, CNC machines can handle it all. Learning to use CNC machines effectively involves understanding CAD/CAM software, G-code/M-code, and selecting the right tools for the job.

If you’re interested in investing in CNC spindle motors, take a look at the wide variety of spindles available at SpindleMotorShop.com. They offer options tailored to both hobbyists and industrial-scale manufacturers.

FAQs

1. What is CNC machining?

CNC machining is a process that uses computer control to automate tools and machines for manufacturing parts.

2. What are the most common types of CNC machines?

The most common types are CNC milling machines, CNC lathes, CNC routers, and CNC plasma cutters.

3. What software is used with CNC machines?

CAD/CAM software like AutoCAD and Fusion 360 is commonly used to design parts and convert those designs into G-code.

4. Why is precision important in CNC machining?

Precision ensures that parts meet exact design specifications, which is critical in industries like aerospace and medical manufacturing.

5. Can CNC machines work with wood?

Yes, CNC routers are particularly suitable for machining wood and can produce intricate designs for furniture and other wood-based products.