Unlocking the Potential of CNC Shields: A Comprehensive Guide

Are you ready to dive into the world of CNC machining and Arduino-based control systems? If so, you’re in the right place! This article will explore the ins and outs of CNC shields, particularly focusing on the Arduino CNC shield and its various applications. Whether you’re a hobbyist looking to upgrade your 3D printer or a professional seeking to enhance your CNC machine’s capabilities, understanding CNC shields is crucial. Let’s embark on this journey to unlock the full potential of these powerful tools!

What is a CNC Shield and Why is it Important?

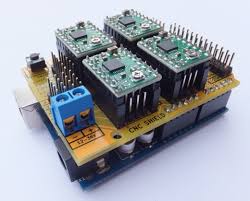

A CNC shield is a hardware component that acts as an interface between an Arduino board and stepper motor drivers. It’s designed to simplify the process of controlling CNC machines, 3D printers, and other motorized systems. The CNC shield allows you to connect multiple stepper motors and control them simultaneously, making it an essential tool for various projects.

The importance of CNC shields lies in their ability to streamline the wiring process and provide a centralized control system. By using a CNC shield, you can easily manage multiple axes, limit switches, and even spindle control without the need for complex circuitry.

How Does the Arduino CNC Shield Work?

The Arduino CNC shield works by translating the signals from the Arduino board into commands that the stepper motors can understand. It acts as a bridge between the software (like GRBL) and the hardware (stepper motors and drivers).

Here’s a basic overview of how it functions:

- The Arduino board receives G-code commands from a computer.

- These commands are processed by firmware like GRBL.

- The CNC shield takes the processed signals and distributes them to the appropriate stepper drivers.

- The stepper drivers then control the individual motors, translating the signals into precise movements.

This process allows for accurate control of multiple axes, enabling complex machining operations or 3D printing tasks.

What Are the Key Features of the CNC Shield V3?

The CNC Shield V3 is a popular variant that offers several improvements over its predecessors. Some of its key features include:

- Support for up to 4 stepper motors

- Compatible with A4988 and DRV8825 stepper drivers

- Onboard voltage regulation

- Spindle enable and direction control

- Support for limit switches and probe inputs

- GRBL v0.9 and v1.1 compatibility

These features make the CNC Shield V3 a versatile choice for many projects, from small DIY CNC routers to more complex machining setups.

How to Connect Stepper Motors to a CNC Shield?

Connecting stepper motors to a CNC shield is a straightforward process, but it requires attention to detail. Here’s a general guide:

- Insert the stepper driver modules (e.g., A4988) into the appropriate sockets on the shield.

- Connect the stepper motors to the corresponding terminals on the shield. Typically, you’ll have four wires per motor.

- Ensure the power supply is connected to the shield’s power input terminals.

- Double-check all connections before powering on the system.

Remember, the exact wiring may vary depending on your specific stepper motors and the CNC shield model you’re using. Always refer to the manufacturer’s documentation for precise instructions.

What Software is Used with CNC Shields?

The most commonly used software with CNC shields is GRBL. GRBL is an open-source firmware that runs on Arduino and interprets G-code commands, translating them into motor movements.

To use GRBL with your CNC shield:

- Download the GRBL firmware from the official GitHub repository.

- Use the Arduino IDE to upload the firmware to your Arduino board.

- Configure GRBL settings according to your machine’s specifications.

Other software options include:

- Universal G-code Sender (UGS): A Java-based G-code sender and CNC controller.

- bCNC: A Python-based G-code sender with advanced features.

- Easel: A web-based design and control software, popular with Inventables X-Carve users.

Can I Use a CNC Shield Without GRBL?

Yes, it’s possible to use a CNC shield without GRBL, although GRBL is the most common firmware used. If you want to create a custom control system, you can write your own Arduino sketch to control the stepper motors directly.

Here’s a basic example of how you might control a single stepper motor without GRBL:

#define STEP_PIN 2

#define DIR_PIN 3

#define ENABLE_PIN 8

void setup() {

pinMode(STEP_PIN, OUTPUT);

pinMode(DIR_PIN, OUTPUT);

pinMode(ENABLE_PIN, OUTPUT);

digitalWrite(ENABLE_PIN, LOW); // Enable the motor

}

void loop() {

digitalWrite(DIR_PIN, HIGH); // Set direction

for(int i = 0; i < 200; i++) { // 200 steps for a full rotation

digitalWrite(STEP_PIN, HIGH);

delayMicroseconds(500);

digitalWrite(STEP_PIN, LOW);

delayMicroseconds(500);

}

delay(1000); // Wait a second before reversing

digitalWrite(DIR_PIN, LOW); // Reverse direction

// ... repeat steps in opposite direction

}While this approach gives you more control, it also requires more programming knowledge and doesn’t provide the advanced features that GRBL offers out of the box.

How to Troubleshoot Common CNC Shield Issues?

When working with CNC shields, you may encounter some common issues. Here are a few troubleshooting tips:

- Motors not moving:

- Check power connections

- Verify stepper driver installation

- Ensure GRBL is configured correctly

- Erratic movement:

- Check for loose connections

- Verify correct microstepping settings on drivers

- Ensure adequate power supply

- Limit switches not working:

- Check wiring connections

- Verify GRBL configuration for limit switches

- Test switches with a multimeter

- Overheating issues:

- Check current limiting on stepper drivers

- Ensure adequate cooling for drivers and motors

- Verify power supply voltage is within specified range

Remember, careful wiring and proper configuration are key to avoiding most issues with CNC shields.

What Are the Limitations of CNC Shields?

While CNC shields are versatile and useful, they do have some limitations:

- Limited power handling: Most CNC shields are designed for smaller motors and may not be suitable for large industrial machines.

- Fixed axis configuration: The standard layout is for 3 axes (X, Y, Z), which may not suit all projects.

- Limited expansion options: While some shields support add-ons, they’re not as flexible as custom-built control systems.

- Dependence on Arduino: Performance is limited by the Arduino’s processing power.

For more advanced applications, you might need to consider more powerful control systems. However, for many hobbyist and small-scale professional projects, CNC shields offer an excellent balance of functionality and ease of use.

How to Choose the Right CNC Shield for Your Project?

Selecting the right CNC shield depends on several factors:

- Number of axes: Ensure the shield supports the number of motors you need to control.

- Compatibility: Check if the shield is compatible with your Arduino board and preferred stepper drivers.

- Additional features: Consider if you need support for limit switches, spindle control, or other features.

- Project scale: For larger projects, you might need a shield with higher current handling capabilities.

For most small to medium-sized projects, a CNC Shield V3 is a great starting point. It offers good compatibility and features at a reasonable price point.

Conclusion: Embracing the Power of CNC Shields

CNC shields have revolutionized the way hobbyists and small-scale manufacturers approach CNC machining and 3D printing. By providing an affordable and accessible interface between Arduino boards and stepper motors, these shields have opened up a world of possibilities for DIY enthusiasts and professionals alike.

Key takeaways:

- CNC shields simplify the process of controlling multiple stepper motors.

- They’re compatible with popular firmware like GRBL, making them easy to use.

- While they have some limitations, CNC shields are excellent for a wide range of projects.

- Proper wiring and configuration are crucial for optimal performance.

- With the right setup, you can achieve professional-grade results on a budget.

Whether you’re looking to build a CNC router, upgrade your 3D printer, or create a custom machining solution, a CNC shield could be the key to unlocking your project’s potential. Remember to choose the right shield for your needs, and don’t hesitate to explore the vast community resources available for support and inspiration.

For those looking to take their CNC projects to the next level, consider exploring high-quality spindles for CNC routers to complement your CNC shield setup. With the right combination of control hardware and precision spindles, you’ll be well-equipped to tackle even the most demanding projects.

Happy making, and may your CNC adventures be both rewarding and precise!