Introduction

A water-cooled spindle is an electro-spindle that controls the operating temperature through water circulation cooling. It is widely used in high-speed, high-precision CNC machine tools and machining centers. Its design aims to ensure the stability and life of the spindle in a long-term high-load working environment through an efficient heat dissipation system. This article will detail the working principle, structural design, and application of water-cooled electro spindles in various industries.

Cooling circulation system

The core of the water-cooled electro spindle is its internally designed cooling circulation system. The cooling water flows along the water channel inside the spindle, absorbs the heat generated by the motor and bearings, returns to the cooling device for cooling, and so on. This process ensures that the spindle can continuously dissipate heat when running at high load, prevent overheating, and provide the stable operation of the equipment.

Temperature control

In some high-precision machining occasions, the water cooling system has a temperature sensor and control system. These sensors can monitor the temperature of the spindle and motor stator in real time and automatically adjust the cooling water flow or the cooling device’s output power through the control system to ensure that the spindle always works within a reasonable temperature range. The temperature control system not only improves the service life of the spindle but also enhances the accuracy and consistency of processing.

Structural design

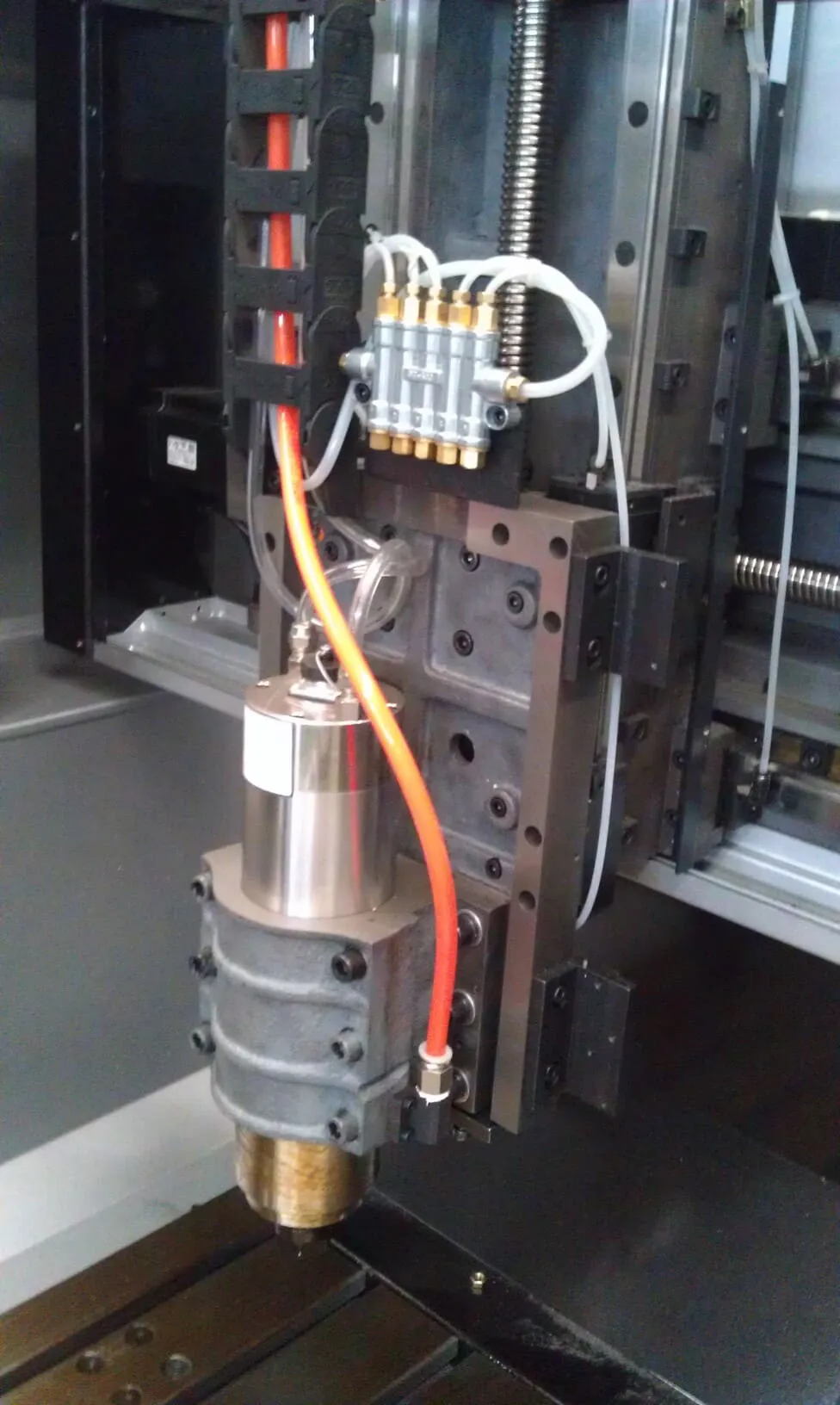

The structural design of the water-cooled electro spindle is an essential factor in achieving efficient cooling. Special water channels are set inside the spindle housing. These water channels are close to the heat-generating components, such as the motor stator and bearings, and the heat generated by these components is effectively taken away by the water flow. At the same time, the water flow forms a heat insulation barrier between the housing and the motor stator, preventing the heat generated by the motor from affecting the accuracy and stability of the spindle. This design ensures the cooling effect of the spindle during high-speed operation, thereby improving the strength and accuracy of processing.

Application field

Water-cooled electro spindles are often used in occasions that require long-term continuous high-speed operation due to their excellent heat dissipation performance and stability. It is particularly suitable for fields such as high-speed processing, precision grinding, drilling, milling processing centers, etc., which have strict requirements on processing accuracy and surface quality. In aerospace, precision mold manufacturing, and optical parts processing industries, water-cooled electro spindles have become necessary equipment for improving processing efficiency and quality.

Conclusion

Water-cooled electric spindles ensure stable operation under high-load environments through cooling circulation systems, temperature control, and sophisticated structural design. Its wide application in precision processing fully demonstrates its advantages of efficient heat dissipation and precise control. As the manufacturing industry continues to increase its requirements for high precision and high efficiency, the application prospects of water-cooled electro spindles will be broader.

Summary FAQ based on the article

1. What is the core function of a water-cooled electro spindle?

The core function of a water-cooled electro spindle is to control the operating temperature of the spindle through water circulation cooling to ensure its stability and long life in a high-load working environment.

2. How can the spindle temperature be effectively controlled?

Some water-cooled electro spindles are equipped with temperature sensors and control systems to monitor the spindle temperature in real-time and automatically adjust the cooling water flow or the output of the cooling system to ensure that the spindle operates within a reasonable temperature range.

3. What is unique about the structural design of a water-cooled electric spindle?

The water-cooled electric spindle has a unique water channel inside the shell, close to the heat-generating components such as the motor stator and bearings. The water flow takes away the heat and forms a heat insulation barrier between the shell and the motor stator to maintain the precision and stability of the spindle.

4. What industries are water-cooled electro spindles suitable for?

Water-cooled electro spindles are widely used in industries that require long-term high-speed operation and high-precision processing, such as aerospace, precision mold manufacturing, and optical parts processing.

5. How does the temperature control system of the water-cooled electro spindle improve the processing accuracy?

The temperature control system ensures that the spindle works within a constant temperature range by adjusting the flow of cooling water and the output of the cooling device in real-time, thereby improving the stability and accuracy of the processing.

- RicoCNC has a team of professionals who have been engaged in the design, production, sales, and maintenance of electro spindles for many years. Our company accepts the purchase of various types of CNC spindles.

water-cooled CNC spindle motors

Edge banding machine spindle motors.

- If you need any CNC spindle, please contact us.