Introduction

In the world of CNC routers, two critical components often stand out when discussing performance: the CNC spindle and the universal drive system. While both are crucial in powering and controlling the router, they serve different functions and offer varying benefits depending on the specific application. This article will explore the distinctions between CNC spindles and universal drive systems, helping you understand which one may be best suited for your machining tasks. Whether you’re new to CNC technology or looking to optimize your current system, this article is a must-read for anyone aiming to make informed decisions in precision manufacturing.

Key Functions and Roles

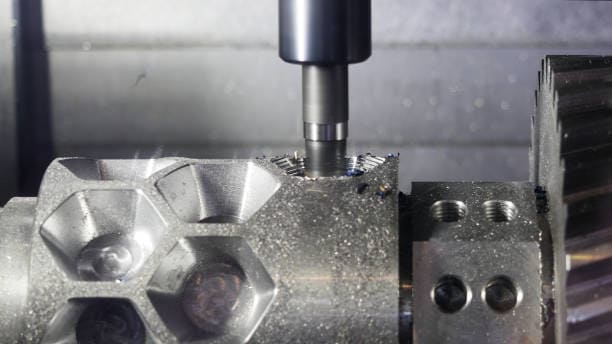

Both CNC spindles and universal drive systems are essential components in CNC routers, but they play distinct roles. A CNC spindle drives the cutting tool at high speeds, providing the torque needed for precision machining. On the other hand, the universal drive system focuses on broader mechanical movement, handling multiple axes and offering flexibility across various applications.

The Role of the CNC Spindle in Precision Machining

The CNC spindle is primarily responsible for the rotation of cutting tools. It ensures high-speed rotation while maintaining stability and accuracy during cutting. The spindle for CNC routers is designed to handle various materials, from wood to metals, making it a critical component for achieving precision in complex machining tasks.

How Universal Drive Systems Enhance CNC Router Performance

Unlike spindles, universal drive systems handle the movement of the CNC machine across multiple axes. They are designed to provide flexibility, enabling CNC routers to perform various tasks such as cutting, drilling, and engraving with high efficiency. Universal drive systems are particularly useful in applications that require more versatility rather than sheer cutting power.

Exploring CNC Universal Drive Systems

CNC universal drive systems offer a different approach to controlling a CNC router. These systems focus on the coordinated movement of the router head and the cutting tool across different axes. While they don’t directly power the tool like a spindle, they are responsible for ensuring that the router operates smoothly and efficiently across a range of operations.

Definition of a CNC Universal Drive System

A CNC universal drive system is a mechanism that controls the movement of a CNC router along its various axes. These systems are designed to work with the spindle, providing accurate positioning for the cutting tool. Universal drive systems can work across multiple operations, making them a versatile option for many CNC applications.

Functionality and Applications

The main functionality of a universal drive system lies in its ability to control the motion of the CNC router, ensuring that each cut or engraving is performed precisely. These systems are ideal for tasks that require movement across multiple dimensions, such as 3D carving or complex material handling. They are commonly used in industries like aerospace and automotive manufacturing, where precision is key.

Comparing CNC Spindles and Universal Drive Systems

Understanding the difference between CNC spindles and universal drive systems helps in selecting the right system for your needs. While both are integral to CNC router performance, their functions differ significantly. A CNC spindle is all about speed and torque, while the universal drive system focuses on motion control and flexibility.

Performance Differences

When comparing performance, CNC spindles excel in high-speed operations that require precise cutting. Universal drive systems, on the other hand, are better suited for operations requiring coordinated movement across multiple axes. If your project demands precision and high rotational speed, a spindle CNC is the ideal choice. For tasks that need flexibility and motion control, a universal drive system may be more appropriate.

| Feature | CNC Spindle | Universal Drive System |

|---|---|---|

| Primary Function | Rotates the cutting tool at high speeds for precision cutting | Controls the movement across multiple axes for coordinated operations |

| Best Suited For | High-speed cutting, drilling, and milling | Engraving, 3D carving, and multi-dimensional tasks |

| Power & Speed | Offers high torque and speed for cutting through tough materials | Focuses on flexibility and movement control, not on power or speed |

| Precision Level | Extremely precise in cutting tasks | Flexible but less precise in high-speed cutting |

| Material Suitability | Ideal for hard materials like metal and dense wood | Best for softer materials or detailed tasks |

Suitability for Various Machining Tasks

For tasks requiring high-speed cutting, such as drilling or milling, CNC router spindles are indispensable. They provide the necessary torque and speed to handle tough materials like metal and dense wood. On the other hand, universal drive systems excel in tasks that require precise movement and flexibility, making them suitable for engraving or intricate 3D carving.

Advantages and Limitations

Each system offers its own set of advantages and limitations. Understanding these can help you choose the best one for your specific application.

Benefits of Using CNC Spindles

CNC spindles provide powerful rotational force, enabling them to cut through tough materials with ease. They are designed to deliver consistent high-speed performance, which is essential for operations like milling, cutting, and drilling. However, they can be limited by their single-axis focus, meaning they are not ideal for multi-dimensional tasks.

Benefits of Using Universal Drive Systems

Universal drive systems offer flexibility and precision across multiple axes, making them ideal for tasks that require coordinated movement. They excel in applications like 3D carving or complex engraving. However, their lack of high-speed rotational power makes them less suitable for tasks that require high torque, such as cutting through metal.

Selection Criteria for CNC Routers

When choosing between a CNC spindle and a universal drive system, several factors must be considered. Your decision should be based on the specific requirements of your projects, such as the material you’re working with and the type of operations you need to perform.

Factors to Consider When Choosing Between a Spindle and a Drive System

When selecting between a CNC spindle or a universal drive system, consider the complexity of the project, material type, and the level of precision required. If high-speed cutting is necessary, a CNC spindle motor is the best choice. For applications requiring intricate movement across multiple axes, a universal drive system offers more flexibility.

Recommendations for Specific Applications

For applications that involve heavy material cutting, such as in metalworking or large-scale woodworking, CNC router spindles are highly recommended. On the other hand, for artistic engraving, detailed carving, or when working with delicate materials, a universal drive system would be more appropriate due to its movement control across multiple dimensions.

Maintenance and Care

Regular maintenance of both CNC spindles and universal drive systems is essential to ensure optimal performance and extend their lifespan. While both systems require specific care, the maintenance routines differ slightly based on their roles in the CNC router.

Maintaining Your CNC Spindle

CNC spindles require regular lubrication and inspection of the bearings to prevent overheating and mechanical failure. Over time, spindles may lose precision due to wear and tear, making routine checks crucial. Additionally, monitoring spindle speed during operations can help detect early signs of failure.

Caring for Your Universal Drive System

Universal drive systems require regular inspection of belts, gears, and motors. Ensuring that all moving parts are properly lubricated and aligned will prevent breakdowns and ensure smooth operations. In addition, checking for any signs of wear or misalignment can prevent costly repairs in the future.

Conclusion

Choosing between a CNC spindle and a universal drive system depends on the specific requirements of your project. CNC spindles offer high-speed cutting capabilities and precision, making them ideal for heavy-duty tasks. Universal drive systems, on the other hand, provide flexibility across multiple axes, making them suitable for more intricate tasks. Understanding the advantages and limitations of each system will help you make an informed decision that ensures optimal performance and efficiency in your CNC router.

FAQs

- Which is more accurate: A CNC spindle or a universal drive system?

CNC spindles tend to be more accurate for high-speed cutting tasks, while universal drive systems offer flexibility but less precision in comparison. - Can I upgrade my CNC router with a universal drive system?

It depends on your CNC router model. Some systems are compatible, but others may require significant modifications. - How do I determine the right spindle speed for my project?

The right spindle speed depends on the material and the cutting tool. Refer to the manufacturer’s guidelines for optimal speeds. - What are the signs of a failing CNC spindle?

Common signs include unusual noise, reduced precision, overheating, and inconsistent speed during operations. - Are universal drive systems compatible with all CNC routers?

Not all universal drive systems are compatible with every CNC router. Always check the specifications of your machine before upgrading.

- RicoCNC has a team of professionals who have been engaged in the design, production, sales, and maintenance of electro spindles for many years. Our company accepts the purchase of various types of CNC spindles.

water-cooled CNC spindle motors

Edge banding machine spindle motors.

- If you need any CNC spindle, please contact us.