Introduction

The CNC spindle market is experiencing rapid evolution, driven by advancements in technology and increasing demand across various industries. As manufacturers seek greater precision and efficiency, understanding the dynamics of the CNC spindle market becomes crucial. This article will delve into the current trends, challenges, and future forecasts of the CNC spindle industry, providing insights that can help businesses make informed decisions. Whether you are a manufacturer, investor, or enthusiast, this comprehensive overview will equip you with the knowledge needed to navigate the CNC spindle landscape effectively.

The Role of CNC Spindles in Manufacturing

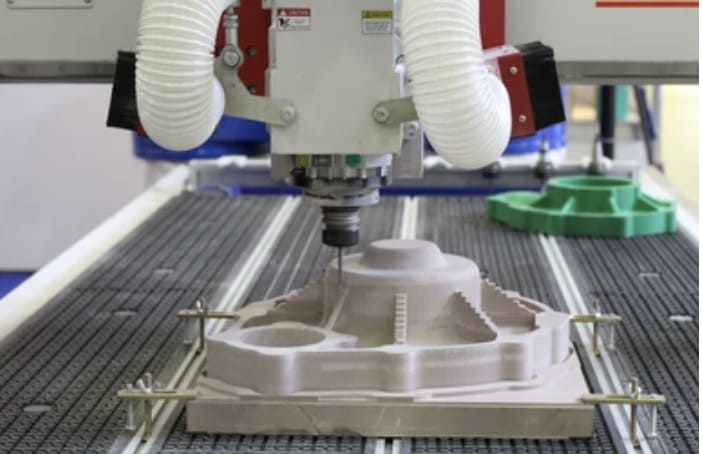

CNC spindles are critical components in modern manufacturing, serving as the driving force behind various machining processes. They are designed to hold and rotate cutting tools at high speeds, enabling precise material removal and shaping. The efficiency and accuracy of CNC machines heavily rely on the performance of the CNC spindle motor.

Importance of CNC Spindles

CNC spindles contribute significantly to manufacturing efficiency by enhancing the speed and quality of production. A well-functioning spindle for CNC machines can reduce cycle times and improve the overall output. Moreover, advancements in spindle technology, such as variable speed control and cooling systems, have further optimized their performance.

How CNC Spindles Affect Production

The impact of CNC spindles on manufacturing extends beyond mere functionality. High-quality CNC router spindles can lead to better surface finishes and tighter tolerances, which are essential for industries like aerospace, automotive, and electronics. As manufacturers strive for excellence, investing in superior spindle motor CNC solutions becomes imperative.

What is a CNC Spindle and How Does it Work?

A CNC spindle is essentially the heart of a CNC machine, responsible for the rotation of the cutting tool. Understanding its operation is vital for anyone involved in CNC machining.

Components of a CNC Spindle

A typical CNC spindle consists of several key components: the motor, bearings, and the tool holder. The CNC spindle motor provides the necessary power, while high-quality bearings ensure smooth and precise rotation. The tool holder secures the cutting tool in place, allowing for accurate machining.

Operational Mechanism

The operation of a CNC spindle begins with the motor driving the spindle shaft. As the shaft rotates, the attached cutting tool engages with the workpiece, removing material to achieve the desired shape. The efficiency of this process is heavily influenced by the design and quality of the spindle, making it a crucial factor in manufacturing success.

Current Trends in CNC Spindle Technology

The CNC spindle industry is witnessing several trends that are shaping its future. Staying informed about these trends is essential for manufacturers looking to maintain a competitive edge.

Increased Automation

Automation is becoming increasingly prevalent in CNC machining. Modern multi spindle CNC machines are equipped with advanced controls that optimize spindle performance and reduce manual intervention. This trend not only enhances productivity but also minimizes human error.

Smart Spindle Technologies

The integration of smart technologies into CNC spindles is revolutionizing the industry. Features like IoT connectivity allow for real-time monitoring and predictive maintenance, ensuring that spindles operate at peak performance. This advancement helps reduce downtime and extend the lifespan of CNC spindles.

How Do CNC Spindles Impact Manufacturing Efficiency?

The efficiency of a manufacturing process is often measured by its ability to produce high-quality products in a timely manner. CNC spindles play a pivotal role in achieving this efficiency.

Speed and Precision

One of the primary advantages of using CNC router spindles is their ability to operate at high speeds without compromising precision. This capability enables manufacturers to complete complex machining tasks quickly, resulting in shorter lead times and increased production rates.

Reduced Waste

By utilizing advanced CNC spindles, manufacturers can minimize material waste. High-precision spindles ensure that cutting tools engage with the workpiece accurately, reducing the likelihood of errors and the need for rework. This efficiency translates into cost savings and a more sustainable manufacturing process.

Advancements in CNC Technology

The CNC spindle market is closely tied to advancements in CNC technology. Understanding these developments can provide insights into future trends.

Enhanced Materials

The use of advanced materials in spindle construction has improved their durability and performance. Materials such as carbon fiber and high-strength alloys are increasingly being utilized to manufacture spindle motors CNC, resulting in lighter and more robust designs.

Improved Cooling Systems

Effective cooling systems are essential for maintaining spindle performance during prolonged machining operations. Recent innovations have led to the development of advanced cooling technologies that prevent overheating and extend the life of CNC router spindles.

Growing Demand for Precision Engineering

As industries evolve, the demand for precision engineering continues to rise. This trend significantly impacts the CNC spindle market.

Industry Applications

Precision engineering is crucial in sectors such as aerospace, automotive, and medical device manufacturing. The need for high-quality components drives the demand for advanced CNC spindles capable of delivering exceptional accuracy and reliability.

Customization Needs

With the increasing complexity of products, manufacturers are seeking customized solutions to meet specific requirements. This trend has led to the development of specialized spindle for CNC router applications, catering to diverse industry needs.

Expansion of CNC Applications Across Industries

The versatility of CNC technology has led to its adoption across various industries, further driving the demand for CNC spindles.

Diverse Industry Adoption

From woodworking to metal fabrication, CNC spindles are utilized in a wide range of applications. The expansion of CNC technology into new sectors, such as electronics and textiles, presents significant growth opportunities for the spindle market.

Innovative Applications

Emerging applications, such as 3D printing and additive manufacturing, are also influencing the CNC spindle landscape. As these technologies gain traction, the need for specialized CNC spindle motors will continue to grow.

Challenges Facing the CNC Spindle Market

Despite the promising outlook, the CNC spindle market faces several challenges that could impact its growth.

High Equipment Costs

The initial investment in CNC technology, including dual spindle CNC machines, can be substantial. Many manufacturers, especially small and medium-sized enterprises, may struggle to afford these advanced systems, limiting their ability to compete in the market.

Technical Challenges and Maintenance

Maintaining CNC spindles requires specialized knowledge and skills. Technical challenges related to spindle performance and maintenance can lead to increased downtime and repair costs, affecting overall productivity.

Projected Market Growth Rates

The CNC spindle market is poised for significant growth in the coming years. Understanding these projections can help businesses strategize effectively.

Market Analysis

According to recent reports, the CNC spindle market is expected to grow at a compound annual growth rate (CAGR) of approximately 6% over the next five years. This growth is driven by the increasing adoption of automation and advancements in spindle technology.

Regional Insights

Emerging markets, particularly in Asia-Pacific and Latin America, are expected to contribute significantly to market growth. The expansion of manufacturing capabilities in these regions presents lucrative opportunities for CNC spindle manufacturers.

Emerging Markets and Geographical Hotspots

Identifying emerging markets is crucial for businesses looking to expand their presence in the CNC spindle industry.

Key Regions

Countries such as China, India, and Brazil are becoming hotspots for CNC spindle adoption. The growing manufacturing sectors in these regions create a demand for high-quality spindle motor CNC solutions.

Investment Opportunities

Investors should consider focusing on these emerging markets, as they offer significant potential for growth. Establishing partnerships with local manufacturers can enhance market entry strategies and drive business success.

Impact of Global Economic Trends on the CNC Spindle Market

Global economic trends play a vital role in shaping the CNC spindle market. Understanding these influences can help businesses navigate challenges and seize opportunities.

Economic Growth and Manufacturing Demand

As global economies recover from recent downturns, the demand for manufactured goods is expected to rise. This increase in manufacturing activity will drive the need for efficient and reliable CNC spindles.

Trade Policies and Regulations

Trade policies and regulations can significantly impact the CNC spindle market. Businesses must stay informed about changes in tariffs and trade agreements that could affect the import and export of CNC machinery and components.

Innovations Leading to Market Expansion

Innovation is a key driver of growth in the CNC spindle market. Staying ahead of technological advancements is essential for manufacturers.

Research and Development

Investing in research and development (R&D) is crucial for developing cutting-edge spindle technologies. Companies that prioritize R&D are more likely to introduce innovative products that meet the evolving needs of the market.

Collaboration with Tech Firms

Collaborating with technology firms can lead to the development of advanced CNC spindle solutions. These partnerships can facilitate the integration of smart technologies and improve overall spindle performance.

Sectors Poised for Significant CNC Spindle Adoption

Certain sectors are expected to lead the way in CNC spindle adoption. Identifying these sectors can help businesses target their marketing efforts effectively.

Aerospace and Defense

The aerospace and defense industries require high-precision components, making them prime candidates for CNC spindle technology. The demand for lightweight and durable materials further drives the need for advanced CNC spindles.

Medical Device Manufacturing

As the medical device industry continues to grow, the demand for precision-engineered components is increasing. CNC spindles play a crucial role in producing high-quality medical devices, presenting significant opportunities for manufacturers.

Leading Manufacturers and Their Market Strategies

Understanding the competitive landscape is essential for businesses looking to succeed in the CNC spindle market.

Major Players

Leading manufacturers in the CNC spindle industry include companies like Siemens, Bosch Rexroth, and SKF. These companies are known for their innovative products and strong market presence.

Market Strategies

Successful manufacturers often focus on product differentiation and customer service. By offering tailored solutions and exceptional support, they can build long-lasting relationships with clients and gain a competitive edge.

Understanding Market Entry Barriers

Entering the CNC spindle market can be challenging due to various barriers. Recognizing these obstacles is crucial for prospective businesses.

High Capital Investment

The significant capital required to develop and manufacture CNC spindles can deter new entrants. Companies must be prepared to invest in advanced technology and skilled labor to compete effectively.

Regulatory Compliance

Navigating regulatory requirements can be complex, especially for businesses looking to enter international markets. Ensuring compliance with safety and quality standards is essential for gaining customer trust and market acceptance.

Investment Strategies for Maximum ROI

For investors, understanding the CNC spindle market dynamics is key to maximizing returns on investment.

Diversification

Investing in a diverse range of CNC spindle products can mitigate risks and enhance potential returns. By exploring various market segments, investors can capitalize on emerging trends and opportunities.

Long-Term Partnerships

Building long-term partnerships with manufacturers and suppliers can provide stability and growth potential. Collaborating with established players in the CNC spindle market can lead to shared resources and expertise.

Conclusion

The CNC spindle market is poised for significant growth, driven by advancements in technology and increasing demand across various industries. By understanding the key factors influencing this market, businesses can make informed decisions and capitalize on emerging opportunities. As the landscape continues to evolve, staying abreast of trends and innovations will be crucial for success.

Key Takeaways

- CNC spindles are essential for manufacturing efficiency and precision.

- The market is projected to grow at a CAGR of 6% over the next five years.

- Emerging markets, particularly in Asia-Pacific, present significant growth opportunities.

- Innovations in spindle technology, such as smart features, are driving market expansion.

- Collaboration and investment in R&D are key strategies for success in the CNC spindle industry.

By focusing on these critical aspects, stakeholders can navigate the CNC spindle market effectively and position themselves for long-term success.

- RicoCNC has a team of professionals who have been engaged in the design, production, sales, and maintenance of electro spindles for many years. Our company accepts the purchase of various types of CNC spindles.

water-cooled CNC spindle motors

Edge banding machine spindle motors.

- If you need any CNC spindle, please contact us.