Introduction

Spindle speed is a critical element in CNC machining, affecting everything from material removal rates to the precision of cuts. When machining precious metals like silver, spindle speed becomes even more important. In this article, we’ll discuss why spindle speed matters, the factors that influence spindle selection, and tips to ensure you’re using the right speed for your CNC projects.

“Mastering spindle speed is the key to unlocking high-quality CNC machining, especially when working with sensitive materials like silver.” — CNC Machining Expert

Understanding CNC Spindle Speeds

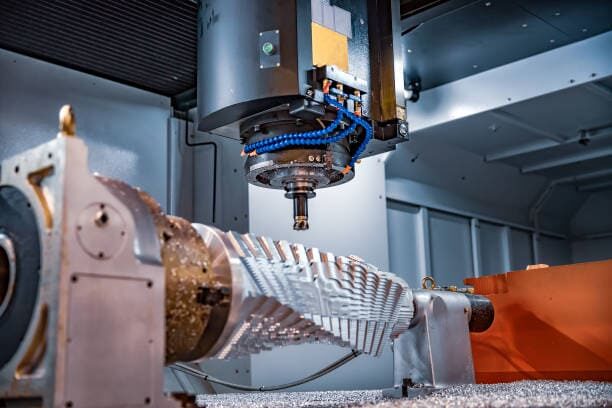

The Basics of Spindle Speed in CNC Machining

In CNC machining, spindle speed refers to the number of revolutions per minute (RPM) that the spindle performs. The speed of the spindle determines how quickly a tool can remove material and how much heat is generated during the process. Adjusting the spindle speed for softer metals, like silver, is crucial for preventing damage to both the material and the cutting tool.

Importance of Spindle Speed for Precision and Efficiency

Spindle speed directly impacts both the precision of your cuts and the efficiency of your machine. Higher speeds are generally more efficient for material removal, but excessive speed can lead to tool wear and a rough surface finish. On the other hand, lower spindle speeds can produce finer details but might require more passes to remove the same amount of material.

Choosing the Right Spindle for Silver CNC Projects

Factors to Consider When CNC Machining Silver

When working with silver, spindle speed isn’t the only factor to consider. You also need to take into account the spindle motor power, feed rate, and tool diameter. Silver, being a relatively soft metal, requires a spindle that can maintain consistent speed without overheating. A CNC spindle motor with variable speed control allows you to adjust the speed depending on the project.

Recommended Spindle Speeds for Silver

For CNC machining silver, the ideal spindle speed is generally between 8,000 and 12,000 RPM. This range allows for efficient material removal without generating too much heat, which could damage the silver or the cutting tool. If you’re working on a more delicate project or detailed engraving, you might want to lower the spindle speed to around 6,000 RPM to maintain precision.

The Role of Spindle Speed in Material Removal Rates

How Spindle Speed Affects Silver Machining

The material removal rate (MRR) is a key performance indicator in CNC machining. With silver, a soft metal, spindle speed significantly influences MRR. Higher spindle speeds increase the rate at which material is removed, but excessive speed can compromise tool life and lead to overheating. Therefore, balancing spindle speed and feed rate is crucial for effective silver machining.

Optimizing Spindle Speed for Better Finish and Tool Life

To achieve the best results when machining silver, it’s important to optimize spindle speed not only for material removal but also for surface finish and tool life. High-speed machining can generate heat that deforms the silver, whereas slower speeds can produce a better surface finish. Experimenting with spindle speed while monitoring the quality of the cut can help you find the ideal balance for your specific project.

CNC Spindle Speeds: Case Studies and Examples

Real-life Applications Demonstrating Spindle Speed Choices

In a real-world scenario, a jeweler might use a high-speed spindle (around 10,000 RPM) to carve intricate designs into silver rings or bracelets. The high speed ensures a smooth finish and quick material removal. On the other hand, a craftsman creating a large silver plaque with simple engravings may opt for a lower spindle speed, around 6,000 RPM, to preserve tool life and prevent overheating during extended periods of use.

Lessons Learned from Machining Silver at Various Speeds

Through hands-on experience, many machinists find that high spindle speeds are beneficial for detailed silver work, as long as cooling mechanisms are in place. Lower spindle speeds are often used when surface finish quality is a higher priority, such as when creating decorative or artistic pieces. By experimenting with different spindle speeds, machinists can find the sweet spot that balances speed, quality, and tool wear.

Selecting the Right Spindle for Silver CNC Projects

Characteristics of Spindles Suitable for Silver

The best spindle for silver CNC machining should have a variable speed feature, allowing operators to adjust speeds between 6,000 and 12,000 RPM. Additionally, spindles with built-in cooling systems, like water-cooled spindles, are preferable for working with silver, as they help dissipate heat during high-speed operations. The CNC router spindle motor must also provide smooth RPM transitions to ensure precision during detailed work.

Comparison of High-Speed vs. Low-Speed Spindles for Silver Machining

When comparing high-speed spindles to low-speed spindles for silver CNC machining, the main difference lies in the finish quality and tool longevity. High-speed spindles, operating above 10,000 RPM, are ideal for quick material removal and detailed work. However, lower-speed spindles (below 8,000 RPM) offer better surface finishes and extended tool life, making them suitable for larger or less intricate designs.

Optimizing Spindle Speed for Enhanced Silver Machining

Techniques for Determining Optimal Spindle Speed

Determining the optimal spindle speed for a silver CNC project involves a combination of factors, including the type of tool, the material thickness, and the complexity of the design. Using a feed-and-speed calculator can help determine the appropriate spindle speed for your specific setup. Additionally, many CNC control software packages offer spindle speed recommendations based on the tool diameter and material type.

Adjusting Spindle Speed for Complex Silver Projects

For complex CNC silver projects, such as intricate engravings or 3D reliefs, adjusting the spindle speed is crucial. Lower spindle speeds often provide better control for detailed work, while higher speeds are useful for broader, less detailed cuts. By adjusting the spindle speed during different phases of a project, machinists can optimize both the cutting speed and the quality of the finish.

Conclusion

Spindle speed is a critical factor in CNC machining silver. By selecting the correct spindle speed, you can ensure precise cuts, efficient material removal, and an optimal surface finish. For most silver projects, a spindle speed between 8,000 and 12,000 RPM is recommended, with adjustments made based on the complexity of the design and the material’s properties.

In summary:

- The recommended spindle speed for CNC machining silver ranges between 8,000 and 12,000 RPM.

- High-speed spindles are suitable for detailed work and quick material removal, while low-speed spindles are better for enhancing surface finish and tool life.

- Using a spindle with variable speed control is essential for adjusting to the unique properties of silver.

- Always consider the balance between spindle speed, tool longevity, and material properties when working with silver.

FAQs

What is the ideal spindle speed for CNC machining silver?

The ideal spindle speed for silver CNC machining typically ranges between 8,000 and 12,000 RPM. The exact speed will depend on the project’s complexity and the tools being used.

Can spindle speed vary based on the type of CNC machine?

Yes, different CNC machines have varying capabilities when it comes to spindle speed. Make sure to match the spindle speed to the machine’s limitations and the material you’re machining.

How does spindle speed affect the quality of the finished product?

Spindle speed directly impacts the surface finish and precision of the finished product. Higher speeds usually result in faster material removal, while lower speeds provide a smoother finish.

Are there risks in using too high or too low spindle speeds for silver?

Yes, using spindle speeds that are too high can lead to overheating and tool wear, while too low spindle speeds may result in a rough surface finish and slower material removal.

Where can I find more resources on spindle speeds for specific materials?

There are many resources available online, including feed-and-speed calculators and CNC software packages that offer spindle speed recommendations based on the tool and material being used.

- RicoCNC has a team of professionals who have been engaged in the design, production, sales, and maintenance of electro spindles for many years. Our company accepts the purchase of various types of CNC spindles.

water-cooled CNC spindle motors

Edge banding machine spindle motors.

- If you need any CNC spindle, please contact us.