Introduction

Belt spindle

Belt spindles are widely used in small and large CNC machining centers, and their speed is usually at most 8000 rpm. The advantage of this spindle is that it is easy to assemble and has less vibration than the gear spindle. However, as the speed increases, the noise of the belt spindle will become louder, and the tension of the belt is difficult to control, which may affect the processing accuracy.

Gear spindle

Gear spindles are mainly used in large and medium-sized CNC machine tools. They use a few pairs of gears to reduce the speed and expand the output torque to meet the demand for output torque at low speed. The main advantage of this type of spindle is its high output force, but it also brings about more excellent noise and vibration, which may hurt finishing.

Direct drive motor spindles

The speed of a direct-coupled spindle can reach 12,000 rpm, but its cutting force is not as good as that of a belt-type spindle, so it is more suitable for processing small parts. The mechanical efficiency of a direct-coupled spindle is higher because the output of the motor can be transmitted to the spindle more completely. However, the direct-coupled spindle has very high requirements for correcting the coupling. If the correction is not good, it will lead to problems such as excessive temperature rise, excessive vibration, excessive deflection, and poor machining accuracy of the spindle.

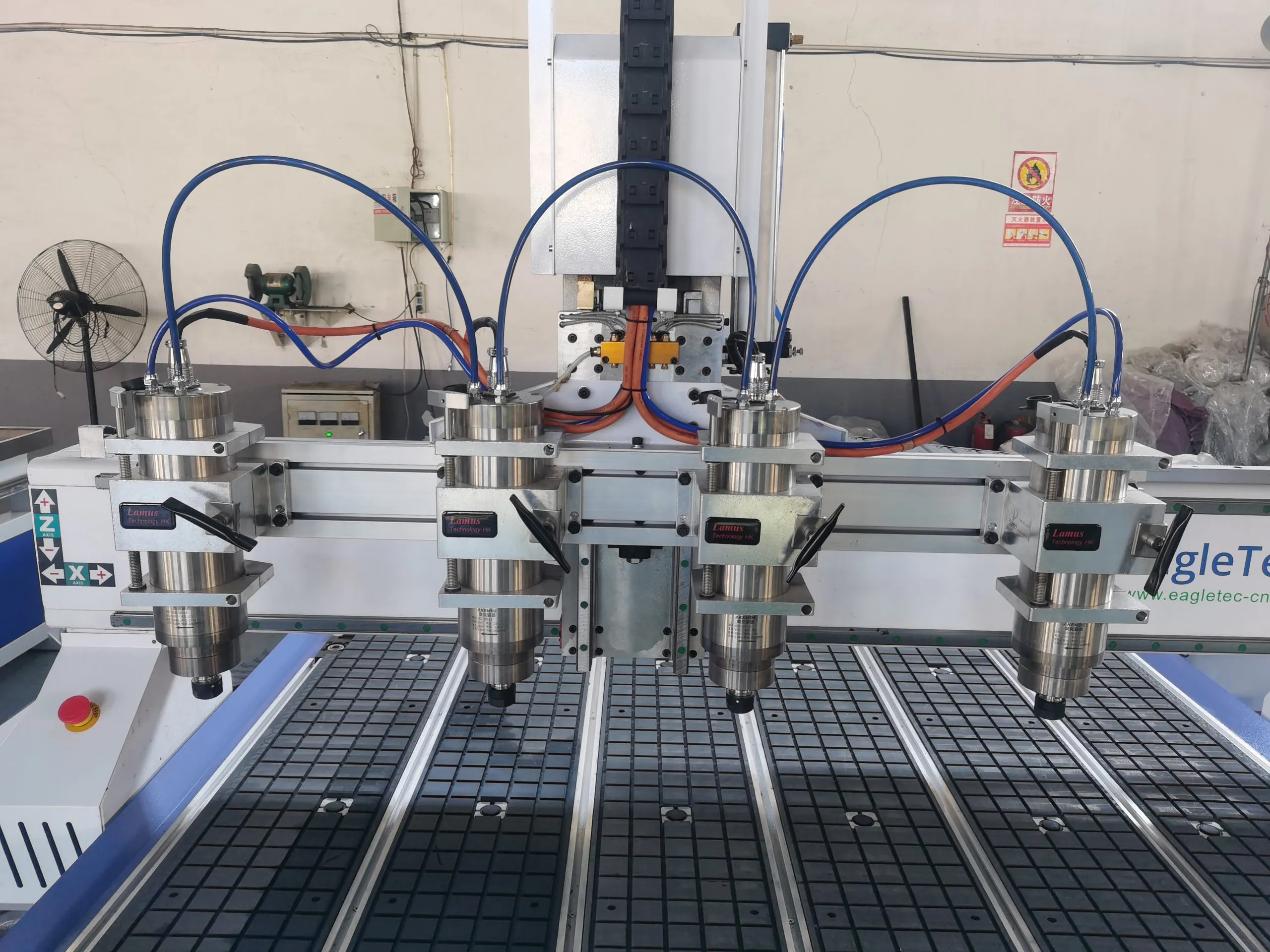

Electro spindle

The electro spindle is the most advanced type; its speed can reach up to 50,000 rpm. Compared with other types of spindles, the electro spindle has the advantages of high sensitivity, low vibration, and no backlash. Its built-in motor design greatly simplifies the structure of the spindle and improves rigidity. However, the electro spindle has exceptionally high requirements for sealing, and about 80% of spindle damage is caused by sealing problems. Therefore, the sealing design and lubrication system of the electro spindle is essential.

Sealing and lubrication of electro spindles

Electro spindles usually use lubricating oil to lubricate the rotating shaft, while the rotating shaft bearings use grease. In actual work, impurities such as lubricating oil, cutting fluid, and dust can quickly enter the rotating shaft bearings, causing the grease to lose or deteriorate and then damage the bearings. For this reason, a labyrinth-like sealing structure can be designed inside the spindle to prevent the invasion of foreign impurities, protect the bearings, and increase their service life.

Conclusion

Summary FAQ based on the article

1. What are the advantages and disadvantages of belt-type spindles?

2. What types of machine tools are gear-type spindles suitable for?

3. What are the main problems of direct-connected spindles?

4. What are the advantages of the electric spindle?

- RicoCNC has a team of professionals who have been engaged in the design, production, sales, and maintenance of electro spindles for many years. Our company accepts the purchase of various types of CNC spindles.

water-cooled CNC spindle motors

Edge banding machine spindle motors.

- If you need any CNC spindle, please contact us.