Introduction

The CNC spindle maintenance process refers to a series of steps and methods for maintaining and repairing the machine tool spindle. As one of the core components of the machine tool, the regular operation of the spindle has an essential impact on the performance and processing quality of the machine tool. Therefore, the standardization and scientificization of the spindle maintenance process are of great significance to the regular operation of the machine tool and the improvement of processing efficiency. The following will introduce the detailed steps and specific contents of the spindle maintenance process.

Spindle inspection

Before starting to repair the CNC spindle, you first need to conduct a thorough inspection of the spindle. The inspection content includes appearance inspection, noise and vibration inspection, electrical parameter measurement, and temperature monitoring. Through these steps, you can preliminarily judge the health status of the spindle.

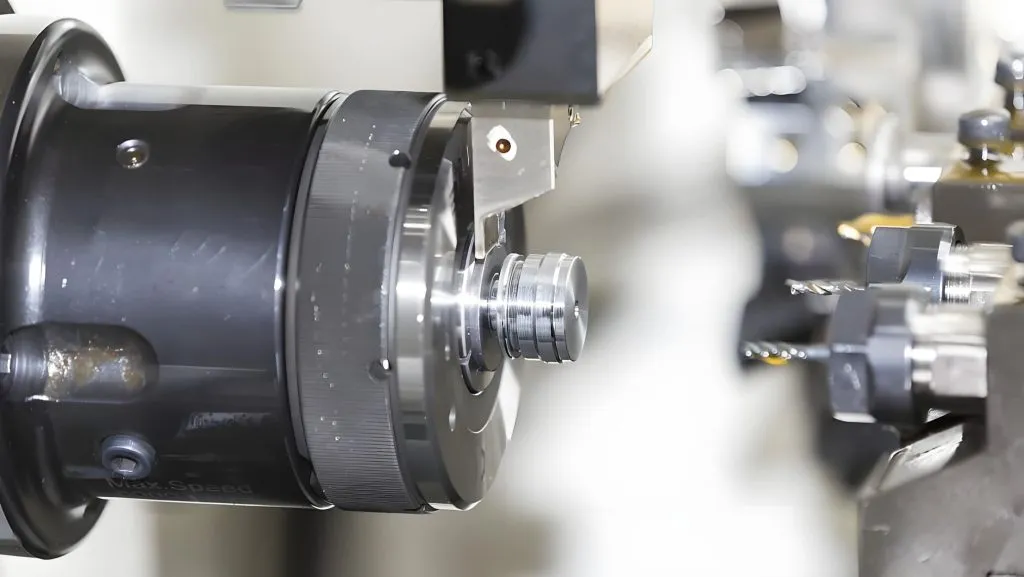

Spindle disassembly

After disconnecting the machine power supply, you first need to remove the accessories on the spindle, such as tools, fixtures, cooling devices, etc. Record the installation position of each component for subsequent reinstallation. Next, remove the transmission and internal components, including direct coupling shafts, bearing caps, bearings, etc. During the disassembly process, operate carefully to avoid damaging the parts.

Troubleshooting

During the disassembly process, troubleshooting can be carried out by visual inspection, hand feel, and tool inspection. Common faults include bearing wear, seal aging, and internal parts damage. For the problems found, it is necessary to formulate corresponding maintenance plans to decide whether to repair or replace the relevant parts.

Parts cleaning and polishing

The disassembled parts should be cleaned to remove oil, dust, and other impurities. For critical components such as bearings and sleeves, polishing is also required to ensure that the mating surfaces are smooth and flawless. After cleaning, the parts should be stored appropriately to avoid secondary contamination.

Replacing spare parts

For parts that have been determined to need replacement, original or certified high-quality spare parts must be used. Before installation, the size and quality of the new parts should be carefully checked to ensure that they match the spindle correctly. During installation, the standard operating procedures or instructions should be followed to avoid damage to the parts or installation errors.

Assembling parts and machining

During assembly, the components should be installed back to their original positions in order according to the records during disassembly. Particular attention should be paid to the installation of bearings, and special tools should be used to avoid damage. The machining accuracy should be ensured to meet the design requirements for parts that need to be machined, such as spindle end covers or sleeves.

Electrical connection and adjustment

After the mechanical part is assembled, electrical connection and adjustment are required. Check whether the power cord, sensor, and control line are connected correctly, and ensure the regular operation of the electrical system through insulation resistance test and current measurement. After completing the electrical connection, the necessary parameter adjustment and calibration of the CNC system are also required.

Grinding test

After assembly and electrical adjustment, a grinding test should be performed to verify the operating status of the spindle. During the test, attention should be paid to the spindle speed, vibration, and temperature to ensure it usually works within the design range. If any abnormality is found during the test, it should be adjusted or repaired in time.

Dynamic balancing and trial run

Finally, the spindle is dynamically balanced when rotating at high speed. After the dynamic balancing is completed, a trial run is performed to observe whether the various parameters of the spindle are normal. Only after the trial run is qualified can it be used commonly.

Conclusion

Maintenance of CNC spindles is a complex and delicate process that needs to be carried out in strict accordance with the steps. From spindle inspection, disassembly, troubleshooting to parts cleaning, assembly and testing, each step is crucial. Through a scientific maintenance process, the service life of the spindle can be effectively extended.

Summary FAQ based on article

1. Why should CNC spindles be inspected?

Inspecting CNC spindles helps to detect potential faults early and ensure that the spindle can correctly diagnose problems during subsequent maintenance.

2. What should be paid attention to during the spindle disassembly process?

The installation position of each component needs to be carefully recorded and handled with caution to avoid damage to the parts.

3. Why is a dynamic balancing test required?

The dynamic balancing test ensures that the spindle remains balanced when rotating at high speeds to avoid unnecessary vibration during processing.

- RicoCNC has a team of professionals who have been engaged in the design, production, sales, and maintenance of electro spindles for many years. Our company accepts the purchase of various types of CNC spindles.

water-cooled CNC spindle motors

air-cooled CNC spindle motors

Edge banding machine spindle motors.

- If you need any CNC spindle, please contact us.