Introduction

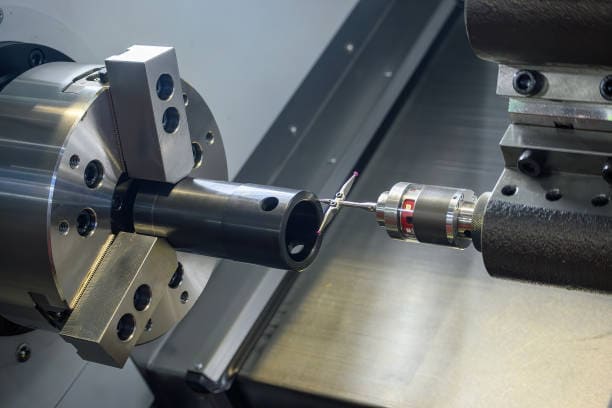

The spindle on a CNC router is one of the most critical components responsible for cutting, engraving, and shaping materials with precision. However, CNC spindle speeds don’t always run at optimal levels, leading to reduced performance and inefficiency. If you’ve ever encountered your spindle slowing down, you’re not alone. This article will delve into the various factors that may cause a CNC spindle to run slower than usual, the steps you can take to troubleshoot, and how to prevent these issues from recurring. It’s a must-read for anyone relying on CNC routers for their production processes.

Factors Affecting Spindle Speed

There are several factors that can cause the spindle on a CNC router to slow down. Mechanical wear and tear, overheating, power supply issues, and improper maintenance are just a few of the culprits. Understanding these variables can help you not only troubleshoot existing issues but also take preventive measures to avoid future slowdowns.

Mechanical Wear and Tear

Over time, the constant operation of a CNC spindle motor can lead to the gradual degradation of its internal components. Bearings, belts, and gears within the spindle for CNC machines may become worn out, leading to a noticeable drop in spindle speed. Routine inspections are crucial to catch these wear and tear signs early.

Temperature Effects on Spindle Performance

Temperature fluctuations, especially overheating, can also affect the performance of a CNC spindle. Excessive heat buildup in the spindle for CNC routers may cause it to slow down or even stop functioning altogether. Proper cooling mechanisms and ventilation systems are essential to maintain the spindle’s speed and performance.

Troubleshooting Slow Spindle Speeds

If your spindle speed is inconsistent, you can troubleshoot by examining several key areas. Issues could range from inadequate power supply to worn-out components or even environmental factors affecting performance.

Inadequate Power Supply Issues

One of the first areas to investigate when dealing with slow spindle speeds is the power supply. Insufficient voltage or unstable power can directly impact the spindle CNC’s ability to operate at its optimal speed. Checking and ensuring a stable power supply can often resolve these issues.

Routine Maintenance Checks

Routine maintenance checks are critical for ensuring that the CNC router spindle motor remains in top working condition. These checks should involve inspecting belts, bearings, and cooling systems to make sure everything is functioning properly.

Causes of Spindle Slowdowns

Several factors can directly cause the spindle to run slower than usual. From improper lubrication to failing components, understanding the root causes can help in preventing more significant issues down the line.

Overheating and Its Impact on Speed

One of the most common causes of a slow spindle CNC is overheating. When the spindle motor operates at high speeds for extended periods, it generates heat, which can cause internal components to expand and lose efficiency. Installing adequate cooling systems can mitigate this risk.

Wear and Tear of Spindle Components

As the spindle components wear down, they naturally become less efficient. Bearings and other moving parts can degrade over time, causing increased friction and reducing the spindle’s speed. Timely replacement of worn components is essential to maintaining optimal spindle performance.

Enhancing CNC Router Performance

There are several ways to boost the performance of your CNC router and ensure that the spindle operates at its full capacity. Upgrading certain components and recalibrating the spindle can help improve overall efficiency.

Upgrading Spindle Components for Better Efficiency

Investing in a multi-spindle CNC machine or upgrading your current CNC router spindle motor can significantly enhance performance. Newer spindle motors are designed to handle higher speeds and torque, providing more efficient and reliable operations.

Tips for Optimizing Spindle Speed

Optimizing spindle speed involves several factors, including material selection, tool wear, and ensuring that the CNC router spindle is properly calibrated. Regular adjustments to spindle speed based on material type can go a long way in improving your machine’s overall performance.

Conclusion

The spindle on a CNC router is a vital component that requires regular maintenance and monitoring. Slow spindle speeds are often caused by mechanical wear, overheating, or power supply issues. By staying proactive with routine checks and addressing any problems as soon as they arise, you can ensure your CNC router runs at peak efficiency. Whether through troubleshooting or component upgrades, optimizing your spindle’s speed is key to long-term success in CNC operations.

FAQs

- Why is maintaining spindle speed important for CNC routing?

Maintaining the proper spindle speed is essential for precision and efficiency, ensuring that materials are cut or shaped accurately without causing excessive wear on the tools. - How often should spindle maintenance be performed?

Spindle maintenance should be performed regularly, typically every 3-6 months depending on usage frequency. Regular checks help avoid costly downtime and extend the spindle’s lifespan. - Can upgrading the spindle improve my CNC router’s performance?

Yes, upgrading to a higher-performance spindle or a multi-spindle CNC machine can significantly improve cutting speed, accuracy, and overall productivity. - Are there any quick fixes for a suddenly slow spindle?

Common quick fixes include checking the power supply, inspecting for overheating, and ensuring that the spindle components are properly lubricated. - Where can I find professional help for spindle issues?

If troubleshooting doesn’t resolve the issue, contacting a professional CNC technician is recommended to properly diagnose and fix spindle-related problems.

| Issue | Cause | Solution |

|---|---|---|

| Overheating | Inadequate cooling or prolonged high-speed operation | Install cooling systems and take breaks between operations |

| Inconsistent Power | Unstable or insufficient voltage | Check power supply and ensure stable voltage |

| Component Wear | Worn-out bearings, belts, or gears | Perform routine maintenance and replace worn components |

- RicoCNC has a team of professionals who have been engaged in the design, production, sales, and maintenance of electro spindles for many years. Our company accepts the purchase of various types of CNC spindles.

water-cooled CNC spindle motors

Edge banding machine spindle motors.

- If you need any CNC spindle, please contact us.Why Does the Spindle on a CNC Router Sometimes Run Slower Than Usual?