Introduction

Edge banding is critical in woodworking, particularly furniture and cabinetry manufacturing. The quality of the edge banding can significantly affect the final appearance and durability of the product. At the heart of this process lies the edge bander spindle, a crucial component that determines the precision and efficiency of the edge banding operation. Choosing the correct spindle for your edge bander is vital to achieving high-quality results, enhancing production efficiency, and ensuring the longevity of your machinery.

The Role of Edge Bander Spindles

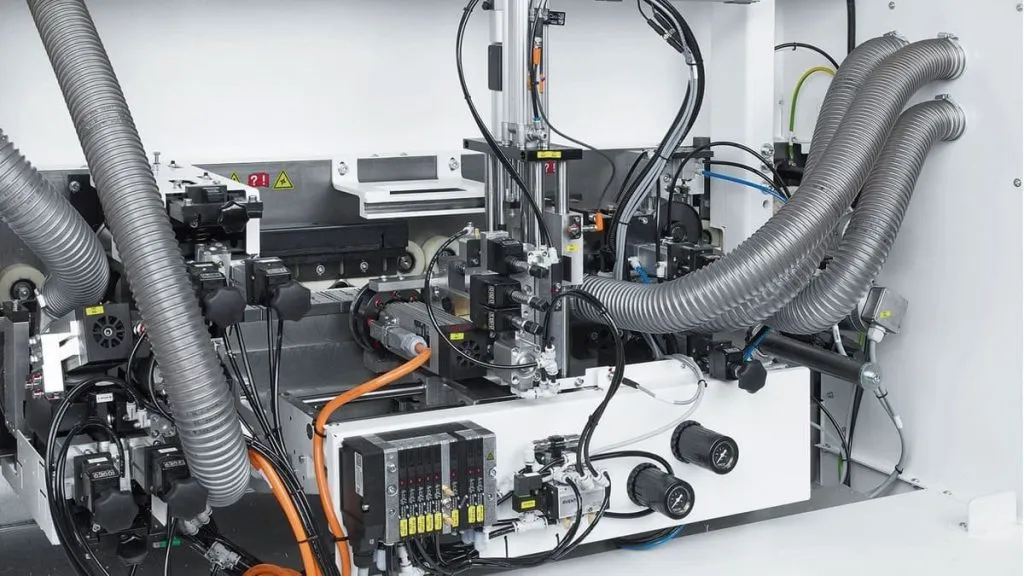

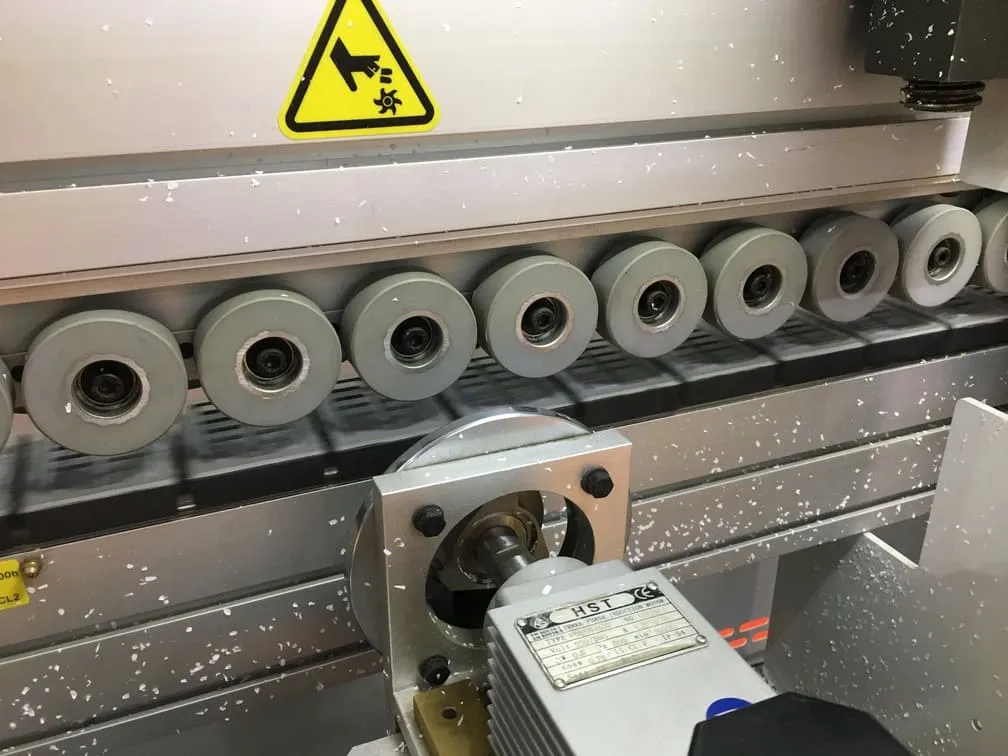

The edge bander spindle is responsible for driving the tools that trim, shape, and smooth the edges of panels during the edge banding process. It plays a vital role in ensuring the edge banding material is applied evenly and securely. The spindle’s speed, power, and precision directly influence the quality of the finished product, making it a critical factor in the overall success of the edge banding process.

Types of Spindles for Edge Banders

There are various types of spindles used in edge banders, each designed for specific applications and materials. For example, high-speed spindles are ideal for delicate operations that require precision and smooth finishes. In contrast, low-speed spindles are better suited for heavy-duty tasks that involve more challenging materials. Additionally, spindles can vary in terms of cooling methods, with some being air-cooled and others water-cooled, depending on the demands of the operation.

Choosing the Best Spindle for Your Edge Bander

Selecting the correct spindle for your edge bander involves considering several factors, including the type of material you work with, the complexity of your edge banding tasks, and the desired finish quality. Choosing a spindle that matches your machine’s capabilities and production needs is essential. Investing in a high-quality spindle can lead to better edge banding results, reduced downtime, and longer machine life.

Conclusion

The edge bander spindle is a critical component in the edge banding process, directly affecting the quality and efficiency of your operations. By understanding the different types of spindles available and carefully selecting the right one for your needs, you can achieve superior edge banding results, increase productivity, and maintain the longevity of your equipment.

Summary FAQ Based on the Article

Q1: What is the role of the edge bander spindle in the edge banding process?

A1: The edge bander spindle drives the tools that trim, shape, and smooth the edges of panels, ensuring even and secure application of edge banding material.

Q2: What factors should I consider when choosing an edge bander spindle?

A2: Consider the material you work with, the complexity of your tasks, and the desired finish quality. Choose a spindle that matches your machine’s capabilities and your production needs.

Q3: How does the choice of spindle affect the edge banding quality?

A3: The spindle’s speed, power, and precision directly influence the quality of the finished product, making it essential to choose the right spindle for high-quality results.

- RicoCNC has a team of professionals who have been engaged in the design, production, sales, and maintenance of electro spindles for many years. Our company accepts the purchase of various types of CNC spindles.

water-cooled CNC spindle motors

Edge banding machine spindle motors.

- If you need any CNC spindle, please contact us.