Introduction

The speed of the spindle is a critical factor in the edgebanding process and has a direct impact on the quality of the finished product. The right spindle speed ensures smooth, precise application of the edgebanding material, while the wrong speed can result in poor adhesion, rough edges, and, even worse, damaged boards. This article explores how spindle speed affects edgebanding quality.

How spindle speed affects edgebanding quality

Optimal spindle speeds for different materials

Common speed-related issues and solutions

Conclusion

Spindle speed plays a critical role in the edgebanding process and directly affects the quality of the finished product. By understanding how spindle speed affects different materials and making the necessary adjustments, you can achieve superior edgebanding results and avoid common issues such as scorching and poor adhesion.

Summary FAQ Based on Articles

Q1: How does spindle speed affect edgebanding quality?

A1: Spindle speed determines how quickly edgebanding material is applied and how well the edge is trimmed and smoothed, affecting the finished product quality.

Q2: What spindle speed should I use for different materials?

A2: For softwoods and plastics, higher speeds are generally better, while for hardwoods and dense laminates, lower speeds are recommended to prevent overheating and ensure proper bonding.

Q3: What should I do if scorching or poor bonding occurs during edgebanding?

A3: Adjust the spindle speed in small increments and inspect the edge bander for any maintenance issues, such as dull blades or improper alignment

- RicoCNC has a team of professionals who have been engaged in the design, production, sales, and maintenance of electro spindles for many years. Our company accepts the purchase of various types of CNC spindles.

water-cooled CNC spindle motors

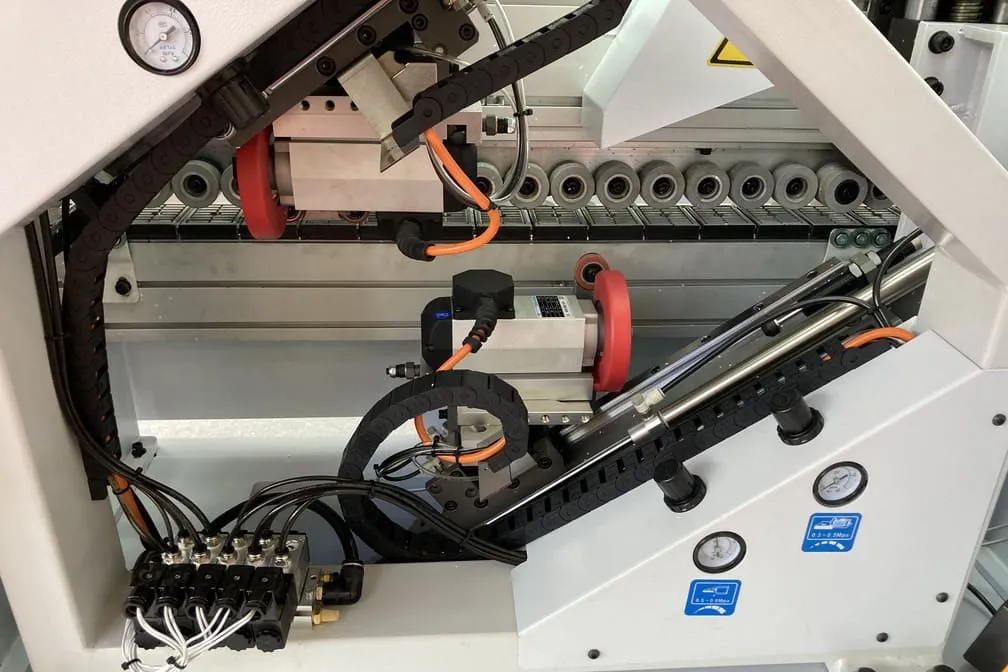

Edge banding machine spindle motors.

- If you need any CNC spindle, please contact us.